About Our

Products

- Home

- Products

- Anisotropic Conductive Film (ACF)

- Anisotropic Conductive Film (ACF) for smart cards

Anisotropic Conductive Film (ACF)

Anisotropic Conductive Film (ACF) for smart cards

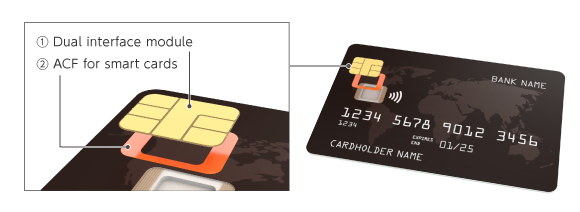

Anisotropic Conductive Film (ACF) optimized for the embedding of functional modules such as dual interfaces and fingerprint sensors in contact/contactless smart cards

-

- Product name

- EH2035H-40

-

- Features

-

- Performs mounting functional modules by adhesion and forming electrical conduction (electric circuits) simultaneously on substrates with low heat-resistance such as PVC, PC, and PET-G.

- Using ACFs as module-embedding materials instead of solder or Ag paste reduces the number of processes and improves production efficiency.

- Modules can be embedded on dual interface cards and smart cards with fingerprint identification by using typical equipment (milling and embedding apparatuses) commonly used in smart card assembly processes.

Related articles

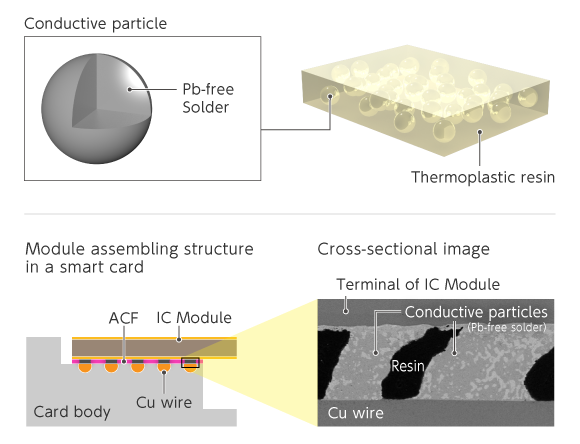

Structure

Specifications

| Product name | EH2035H-40 | |

|---|---|---|

| Connection material | Dual interface module, Fingerprint sensor module | |

| Card substrate (such as PVC, PC, and PET-G) | ||

| Standard length [m] | 100 | |

| Standard width [mm] | 29 | |

| Thickness [µm] | 40 | |

| Conductive particles | Type | Pb-free solder particles |

| Mean particle diameter [µm] | 35 | |

| Pasting conditions | Temperature [℃] | 120 to 140*1 |

| Time [sec] | 1.5 to 3.0 | |

| Pressure [N/module] | 3.0 to 20 | |

| Main bonding conditions | Temperature [℃] | 140 to 160*1 |

| Time [sec] | 0.5 to 1.2*2 | |

| Pressure [N/module] | 60 to 120*3 | |

| Storage condition | At room temperature | |

| Shelf life | Two years after production | |

- *1Temperature of ACF

- *2each step

- *31.5 - 3.5 bar

For the embedding of functional modules such as dual interfaces and fingerprint sensors in Contact/contactless smart cards

Contact and contactless IC cards

Other than these, ACFs for connecting terminals of smart card display modules and battery modules are available. Please feel free to contact us.

caution

Note on the characteristic data given - Data on the characteristics of the products described in this page based on the results of evaluations carried out by the company. This does not guarantee that the characteristics of the product conform with your usage environment. Before use, review the usage conditions based on evaluation data obtained from the equipment and substrates actually used.

Product information

-

Anisotropic conductive film (ACF)

- Anisotropic Conductive Film (ACF) for Chip On Glass for small-to-medium-sized FPDs

- Anisotropic Conductive Film (ACF) for Film On Glass for small-to-medium-sized FPDs

- Anisotropic Conductive Film (ACF) for Film On Glass for large FPDs

- Anisotropic Conductive Film (ACF) for Film On Board for large FPDs

- Anisotropic Conductive Film (ACF) for Film On Board for automobile

- Anisotropic Conductive Film (ACF) for smart cards

- Anisotropic Conductive Film (ACF) for Film On Board / Film for alternative to connector and solder connection

- Anisotropic Conductive Film (ACF) for Film On Glass for Touch panel

- Anisotropic Conductive Film (ACF) for Film On Plastics for Touch panel

- Anti-reflection film

- Optical elastic resin (SVR)

- Adhesive

- Surface mount fuse

- Eye shield material for medical

- Double coated tapes

- Single coated tapes

- Optical devices

- UV curable resin for optical discs

- Sputtering

Optical Semiconductor