This product, INFRA-AID UVS-1000C, has been renewed with a more user-friendly container and is being sold by AirMore Co., Ltd. as “LeakAID LL-100-LA180G” since June 2024 onwards.

For inquiries about this product, please contact AirMore Co., Ltd.

[ Contact information on the product ]

AirMore Co., Ltd. (https://n-airmore.com/

(JP))

Address: 5655 Takayama-Cho, Ikoma-shi, Nara Prefecture, 630-0101 Japan

Tel: +81-743-21-0005

For information on LeakAID LL-100-LA180G, visit https: https://n-airmore.com/leakaid/ (JP)

1. Overview

Infra-Aid™ is a brand of leak repair products developed specifically for repair and maintenance of infrastructure equipment.

“UVS-1000C” UV curable Sealant

Ideal for emergency repair of oil leaks on electrical equipment or other infrastructure. When applied to oil pipe or flange leaks on aging or deteriorated equipment, it incorporates and integrates surface oil to bond tightly with the part repaired. Instant curing after at least one second of UV exposure stops oil leakage and prevents leak paths from developing.

Features

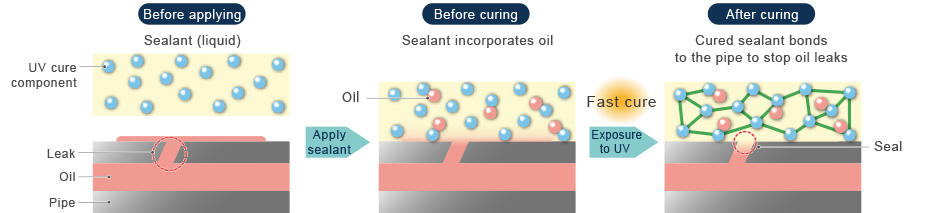

Bonds even to slightly oily surface

Sealant itself blends with and incorporates residual oil, allowing the sealant to come into contact with the bonding surface of the pipe to ensure adhesion to oily surfaces

Formulated for optimal viscosity when applied

Ideal fluidity to resist sagging on vertical surfaces yet become runny to flow into small gaps

Cures quickly with UV

Effective in preventing leak paths from developing

Significantly saves the working time compared to epoxy-based repair materials

Removable after repair

Sealant hardness is designed to enable removal by chipping

How It Works

Demonstration (Video)

Application Examples

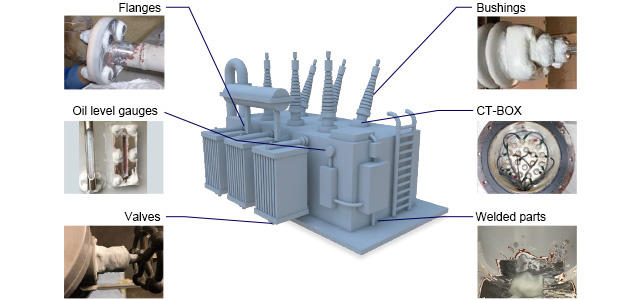

Oil leaks : Can be used for infrastructure equipment repair where complete removal of leaking oil or residual surface oil has been difficult.

Electrical equipment: ∙ Transformers ∙ Shunts

Parts where oil leaks: ∙ Flanges ∙ CT-boxes ∙ Bushing cementing ∙ Weld pinholes

2. How to Use

Surface

preparation

(sanding/

cleaning)

1. Prepare surfaces by removing old paint, rust, and grease

Clean and degrease leaking parts.

Remove paint and rust in advance.

Application

2. Apply the sealant

Apply the sealant to affected parts.

Curing

3. Cure with UV exposure

Immediately cure by exposing to UV light.

Overcoating

4. Apply and cure additional coats

Repeat steps 2–3 to apply at least two coats of sealant.

Work Instructions (Video)

Key Points (Video)

3. Product Information

Specifications

| Product name | UVS-1000C | |

|---|---|---|

| Type | 1 component UV curable acrylic | |

| Property(Uncured/Cured) | White viscous liquid / White solid | |

| Adhesion to various materials *1 | Good | Stainless steel, Cast-iron, Rigid PVC, Acrylic (PMMA), Glass, Galvanized steel, Carbon steel, Brass, Aluminum |

| Fair | Olefin resin (PP, PE) | |

| Very poor | Silicone resin, Fluorine resin | |

| Breakdown voltage [KV/mm] *2 | 52 | |

| Shelf life | 2 years from the date of manufacture (stored unopened at room temperature in a dark place) |

|

| Net weight | 200 g | |

| Container | Lid:PP Body:PE | |

- *1 with #1000 sanding

- *2 Conforming to ASTM D149

Technical Data

1.Adhesiveness to oily surfaces

Test Piece Condition

Adherend: Stainless steel plate (SUS 304), 1000-grit sanded

Cured sealant: UVS-1000C, 1 mm thick, in a diameter of 6 mm

Shear test speed: 0.2 mm/s

Curing conditions: 1 J/cm2@ 365 nm

Steel plate was immersed in hexane solution containing HV Insulating Oil A.

Prepared with a layer of oil by removing the plate and drying the hexane.

Sealant was applied to the steel plate with oil film and cured by UV exposure.

Strength was measured by scratching the cured part horizontally with a shear tester.

Results

| Item evaluated | Results | ||

|---|---|---|---|

| Adhesion to oily surfaces Shear strength |

HV Insulating Oil A concentration |

0 wt% (No oil film) |

8 MPa |

| 15 wt% | 6 MPa | ||

2. Oil resistance (oil absorption of cured parts)

| Item evaluated | Results | Notes | ||

|---|---|---|---|---|

| Oil resistance (oil absorption of cured parts) |

HV Insulating Oil A | < 0.5 wt% | JIS K7114 | |

| Rapeseed oil | ||||

| Hydraulic oil | ||||

4. Documentation

Manuals and Instructional Videos

Click here for news release about this product

5. Inquiry about This Product

This product, INFRA-AID UVS-1000C, has been renewed with a more user-friendly container and is being sold by AirMore Co., Ltd. as “LeakAID LL-100-LA180G” since June 2024 onwards.

For inquiries about this product, please contact AirMore Co., Ltd.

[ Contact information on the product ]

AirMore Co., Ltd. (https://n-airmore.com/

(JP))

Address: 5655 Takayama-Cho, Ikoma-shi, Nara Prefecture, 630-0101 Japan

Tel: +81-743-21-0005

For information on LeakAID LL-100-LA180G, visit https: https://n-airmore.com/leakaid/ (JP)