- Home

- Research & Development

- Technical Notes

- Fine Processing Technology

Technical Notes

Fine Processing Technology

What is a fine processing technology?

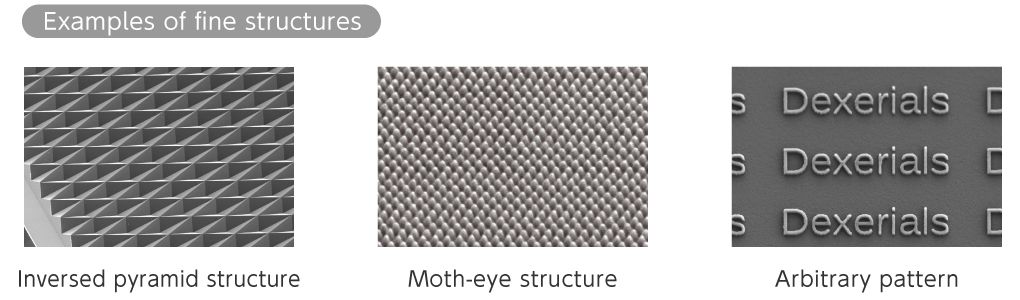

The "fine processing technology" that we are now developing engraves or laminates nano- or micrometer-sized fine figures on base substrates.

Fabricating fine figures on a film or a planar substrate creates novel functions that cannot be obtained only with materials.

Our fine processing technology

We are developing fine processing technologies including mainly the photolithography and nano-imprint technologies that are typically used for manufacturing semiconductor devices. Thanks to the advanced simulation technology today, we can now predict the functions and performance brought about by fine figures more precisely. However, it is hard to fabricate figures accurately in accordance with the simulation results. The key point is to fabricate ideal shapes. Our fine processing technology is for realizing designed functions and we use it in our various products.

Examples of products using this technology

Applications of the photolithography technology|Inorganic diffuser

A number of tiny lenses (microlenses) are precisely engraved on the surface of a transparent substrate such as a glass plate to convert a straight-traveling light beam such as a laser beam into a uniformly expanding light.

The photolithography technology is used to fabricate microlens shapes.

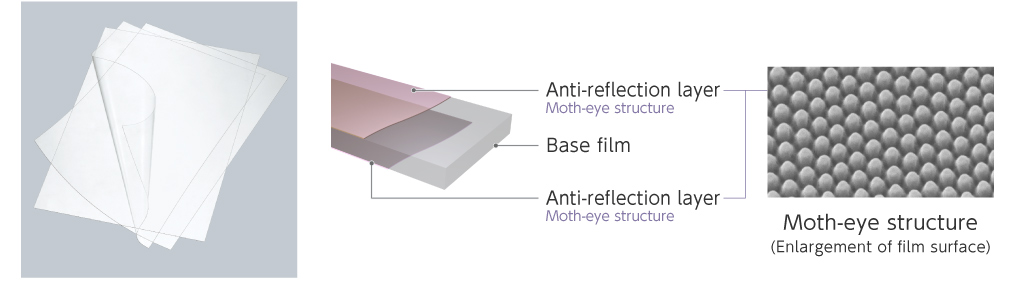

Applications of the imprint technology|Eye shield material for medical

Moth-eye structures are made of nanometer-sized fine unevenness patterns engraved over a film. This moth-eye structure film has a low reflectivity and a high transparency and is used for medical-use eye shields. The roll master processing technology and the imprint technology are used to fabricate this moth-eye structure.

[Reference] Eye shield material for medical

This technology is also used for the following products.

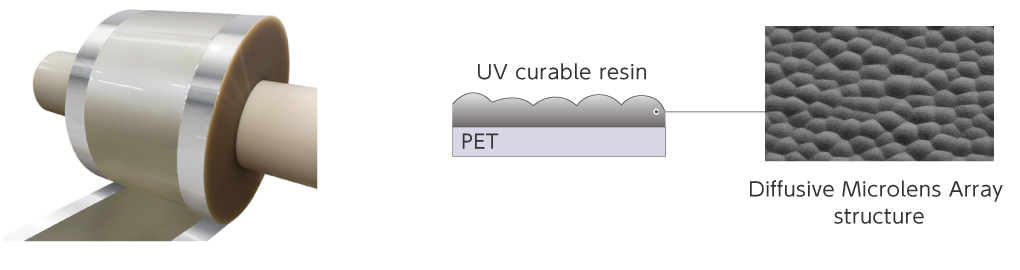

[Reference] Diffusive Microlens Array

Fine processing by the nano-imprint technology

Let us explain in more detail the nano-imprint technology, one of our fine processing technologies. The nano-imprint technology presses a master with fine unevenness patterns on resin-applied substrates to fabricate inverted patterns. The points of this technology are "precision processing of a master" and "accurate and efficient pattern transfer." Let us explain the latter one first, the pattern transfer technique that we use.

Roll-to-roll*1 seamless pattern transfer

*1: This method supplies a rolled base film to the processing machine continuously and then the processed film is wound up into a roll.

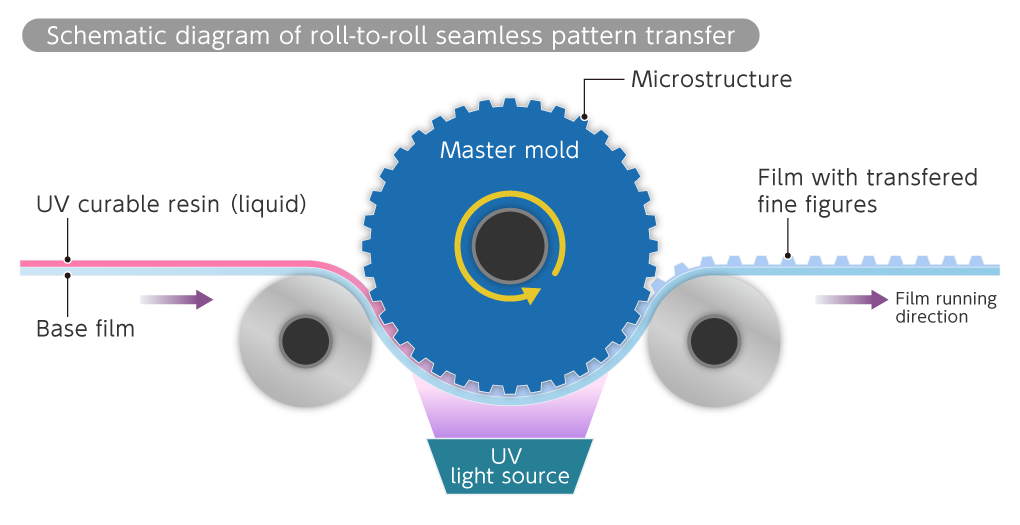

The following figure shows a schematic diagram of a roll-to-roll nano-imprint machine.

A base film moves from left to right. After UV curable resin in applied on the surface of the base film, the film is pressed against a cylindrical master engraved with fine patterns, and then this system is irradiated with UV light, when the patterns on the master is transferred to the base film. The shape of the pattern transferred to the film is an inversion of the pattern on the master. Rotating the cylindrical master enables seamless, reproducible, and efficient pattern transfer.

Next, the technique of processing a master will be explained.

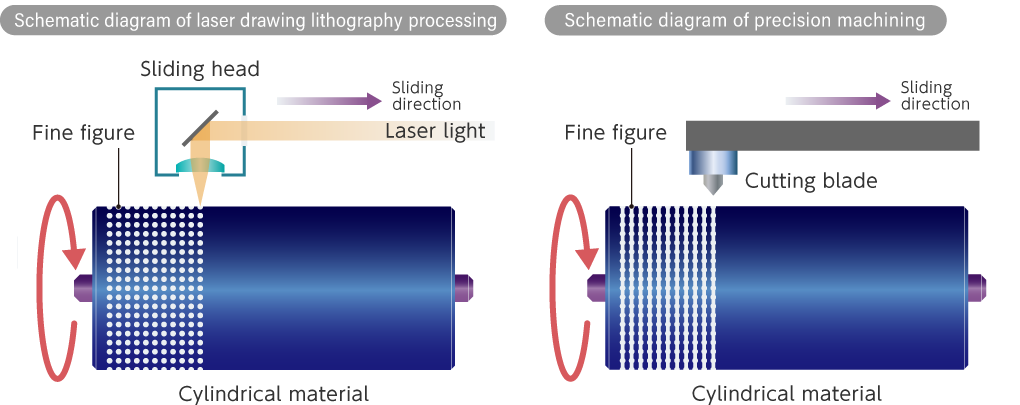

We process the masters used for the roll-to-roll nano-imprint machine in-house. A cylindrical base material for a master is engraved with a fine unevenness pattern while it is rotated. For this process, either lithography processing using a laser beam, or precision machining using a bite is selected according to the target shapes and sizes.

The following figures show the schematic diagrams of cylindrical master processing by lithography processing and by precision machining.

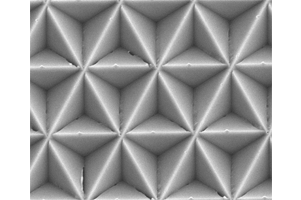

Examples of structures transferred by using masters for fine processing