- “Fair business practices” means conducting procurement in accordance with prescribed policies and procedures.

- “Transparency” means avoiding any arbitrary actions.

- “Equal opportunities” means providing supplier with a level playing field.

- Home

- Sustainability

- Procurement

Relationships with Society

- Quality Management

- Procurement

- Human Resource, Diversity, Workplace

- Initiatives for Respecting Human Rights

- Health and productivity management

- Occupational Health and Safety, Disaster Prevention

- Contribution to Local Communities

Procurement

Basic Philosophy of Supply Chain Management

- 1.Emphasizing “fair business practices, transparency, and equal opportunities,” the Dexerials Group’s procurement is founded on relationships of mutual trust with suppliers.

- 2.Dexerials also emphasizes cooperative relationship with suppliers in such areas as strengthening technological competence, assuring and improving the quality of parts and maintaining competitive prices.

- 3.To preserve the global environment and realize a sustainable society, Dexerials strives for environmental management together with suppliers by observing the Green Procurement Policy.

- 4.To ensure compliance with laws, regulations, and social standards and to realize contributions to society, Dexerials works not only internally but also with suppliers to achieve practical results.

For fair business practices, transparency, and equal opportunities in transactions

Based on the Basic Philosophy of Supply Chain Management, for the implementation of procurement with “fair business practices, transparency, and equal opportunities,” Dexerials is engaged in the following initiatives.

- Respect for social standards and commercial practices, etc.

Regarding procurement, in addition to obviously following the laws of each country, we respect the social standards, ethics and commercial practices, etc. - Anti-corruption

When negotiating the conditions of a transaction with suppliers, including pricing and technical specifications, honesty and faithfulness are essential. With regard to businesspersons engaged in the procurement business, Dexerials ensures complete anti-corruption by prohibiting the reception of money, goods or services that aim to influence or that have the risk of influencing business decisions. - Publicizing the Dexerials procurement policy

In order for suppliers to gain an understanding of Dexerials basic policies regarding legal compliance, respect for human rights, environmental conservation and products/service safety, we regularly holding individual explanatory meetings, for the thoroughness of relevant policies. - Handling information

In addition to striving to disclose appropriate information to suppliers, we conduct appropriate management based on internal policies and procedures related to the Code of Conduct and information security so that confidential information from Dexerials and suppliers is not leaked. - Risk management

In order for transactions to go smoothly, it is necessary for the Procurement Division to strive to prevent and predict dangers that could become factors that inhibit the procurement business. For that reason, when situations occur or may occur that will have a serious impact on business (quality issues, collapse of supplier business, disasters, labor disputes, etc.), crisis management information is shared with the Procurement Division, the Business Division and other relevant divisions and necessary risk avoidance measures are promptly drafted and implemented. - Selection of suppliers

In line with the principles in the Basic Philosophy of Supply Chain Management, we strive to find new suppliers in accord with technical reforms and the supply environment (pricing changes, supply and demand balance, corporate social responsibility, etc.). In the selection of new suppliers, the most important and fundamental requirements are “stable management,” “legal compliance,” “environmental considerations,” and “technical capacity,” and we also evaluate results and expectations for quality, pricing, stable supply, technology services and environmental contribution.

Initiatives for legal compliance

Dexerials is engaged in employee training in order to ensure thorough procurement with “fair business practices, transparency, and equal opportunities.”

Specifically, we confirm compliance with the Act Against Delay in Payment of Subcontract Proceeds, etc., to subcontractors and share information by regularly conducting in-person surveys of the procurement, production management, and other related departments.

Also, we conduct internal audits with regard to the procurement business, and we provide training for relevant parties using improvement guidance based on the audit results.

Promotion of Sustainable Procurement

In light of social demands and other conditions, we have compiled our fundamental approach to social responsibility that we should fulfill with our suppliers and matters that we would like our suppliers to cooperate with us in the Dexerials CSR Procurement Guidelines to sustainability throughout our supply chain. We also seek the understanding and cooperation of all our suppliers of materials and other items.

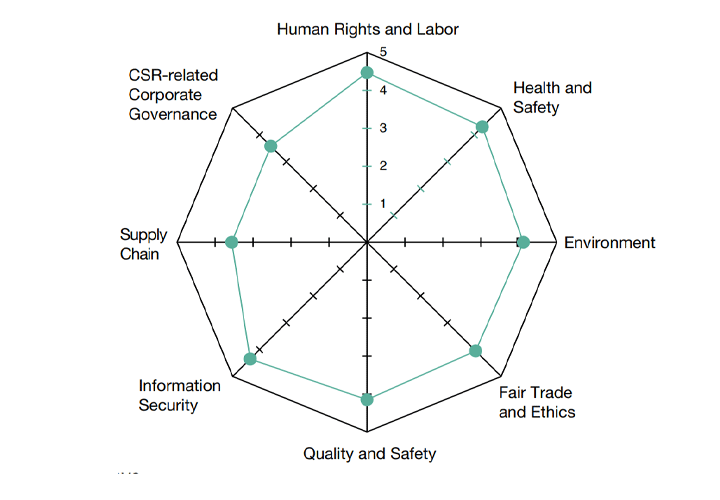

In fiscal 2021, we revised the Guidelines to respond to further changes in social conditions and social demands. In addition to the CSR policy survey that we have conducted for our suppliers in the past, we have conducted a survey for our suppliers who have high dependence on us, on a total of 46 questions, including 42 about the status of initiatives of the matters described in the Guidelines and others about the CSR policies in practice at each company, to understand their initiatives in human rights, labor, health and safety, the environment, and the likes. The survey results are scored and evaluated on a fourpoint scale, and feedbacks are provided to promote cooperative activities to create a sustainable society.

In 2024, we formulated a Sustainability Policy and identified important company-wide issues and ESG-related key issues as we pursue sustainable growth and the enhancement of corporate value. Additionally, we have built a cross-divisional framework for the promotion of sustainability.

Regarding sustainable procurement, KPIs have been set as an ESG key issue (supply chain management), and we are promoting activities accordningly.

Main contents of Dexerials CSR Procurement Guidelines

| Human rights/Labor | Health and safety | Environment | Fair trade/Ethics |

|---|---|---|---|

|

|

|

|

| Quality/Safety | Information security | Supply chain | Corporate governance on CSR |

|---|---|---|---|

|

|

|

|

CSR Procurement Survey Results

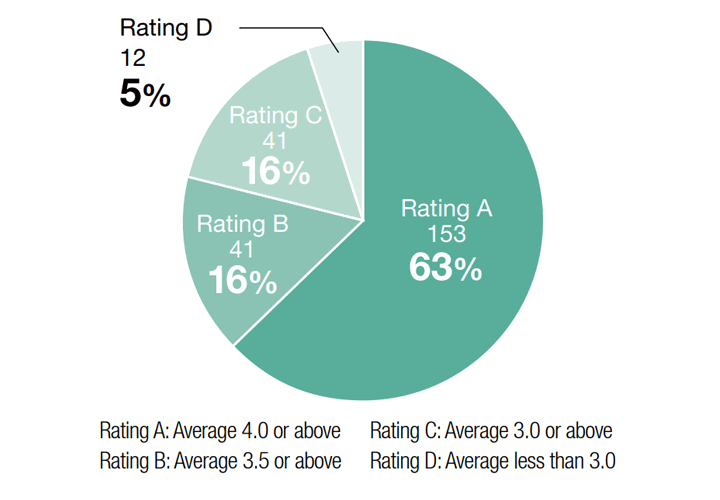

For the CSR Procurement Survey conducted in July 2023, we significantly increased the scope of the survey to further grasp the transaction environment. As a result, we received responses from 252 of the 346 companies surveyed. Going forwards, we will consider measures to raise the response rate, such as reviewing the survey questions, and work on making other improvements.

Based on our analysis of the questionnaire, 95% of our suppliers have achieved the level of commitment we require (rating of C or above) in our overall evaluation.

As for suppliers with low scores, we will look into their procurement conditions and work together to improve problem areas as necessary. We will also prioritize suppliers who agree with our Guidelines by evaluating them appropriately.

| CSR Procurement Survey Overview | |||

|---|---|---|---|

| Survey period | July 2023 | Number of questions | 46 |

| Number of companies surveyed | 346 (252 responses) | Average score of all questions | 4.16 points (on a 5-point scale) |

Percentage by rating rank

Percentage by rating rank Average of all companies

Average of all companiesResponse to Conflict Minerals

Metals produced through illegal mining by antigovernment armed groups have become a global problem, and companies are required to take a responsible procurement stance. Our products also use four metals (gold, tin, tantalum, and tungsten) that are subject to investigation under the U.S. Dodd Frank Act*, and we have received procurement requests from our customer.

Among the raw materials and parts we procure, there are very few mineral-based materials compared to other raw materials, we promote responsible procurement by avoiding the use of risky raw materials and parts, based on our Group policy of “Aiming for 100% procurement from RMI Certified Smelters.”

By obtaining reliable information on the raw materials and parts we procure at the selection stage, confirming trace information on the subject minerals contained in our products, and providing appropriate information to our customers, we fulfill our responsibility as the product supplier.

- *Dodd Frank Act: U.S. Financial Regulatory Reform Act enforced in 2010 as the Wall Street Reform and Consumer Protection Act. In addition to financial regulations, as of 2013, additional provisions require manufacturers listed on the U.S. Securities and Exchange (SEC) to disclose information about their use of the four metals designated as conflict minerals.

Green Procurement

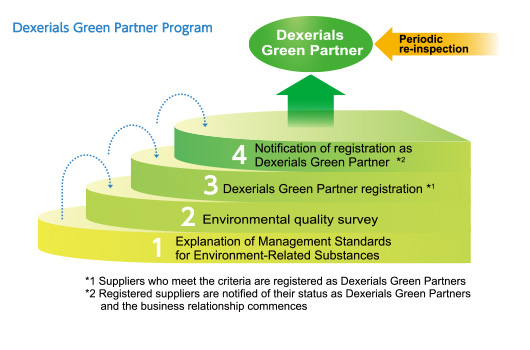

For the purposes of global environmental conservation and the realization of a sustainable society, Dexerials has established a set of Management Standards for Environment-Related Substances, and manufactures products following the Standards. The Standards define controlled substances, which are categorized as substances to be banned immediately, substances to be phased out, or exempted substances. They are also subject to monitoring in order to prevent inclusion in our products or to confirm reduction of their use.

Dexerials designates suppliers who cooperate with these standards as Dexerials Green Partners. In principle, the Dexerials Group procures all raw materials and parts used for its products from suppliers who have been qualified as such partners.

As the process to grant certification as a Green Partner, we start with explaining the “Management Standards for Environment-Related Substances” to suppliers for their understanding. Next, we individually investigate specific matters such as legal compliance to check conformity with our internal certification criteria. Each supplier meeting the certification criteria is certified and registered as a “Green Partner,” and business with such supplier starts.

Through the stable procurement based on the trust relationship with “Green Partners,” the Company will provide high-quality, reliable, and safe products to customers.

About “Management Standards for Environment- Related Substances”

Raw materials, parts, or other elements of our products that are judged by Dexerials to have a significant impact on the global environment or human health are defined as “controlled substances” and are managed accordingly.

These controlled substances are categorized as (1) substances to be banned immediately, (2) substances to be phased out, or (3) exempted substances. They are also subject to monitoring in order to prevent inclusion in our products or to confirm reduction of their use. Our aims here are to conserve the global environment and reduce our impact on the ecosystem. Even if there are no specifications in these standards with regard to certain substances and uses, we comply with the appropriate laws of each country and region in connection to prohibitions and restricted use

The Management Standards for the Environment-Related Substances

Supply Chain Risk Management

The globalization of procurement and logistics, and the advance of global warming, are expected to increase geopolitical risks and intensify natural disasters, making the environment surrounding the supply chain even more severe.

Therefore, reducing these risks to procurement and logistics is an important issue. We are identifying risks faced by our domestic and overseas suppliers and building a system to prepare for and respond to various risks and disasters through digital transformation of monitoring systems and risk assessment systems.

In April 2023, we issued the “Supply Chain BCP Guidelines,” a set of disaster countermeasures that we ask our suppliers to adopt, and we are investigating whether they are taking these countermeasures in line with the Guidelines. The results of the investigation, together with the CSR Procurement Survey, will be used in the selection criteria for suppliers to achieve better supply chain stability.

Response to Procurement Issues

Procurement risks that have arisen recently include the global spread of infectious diseases, dependence on raw material suppliers, and the geopolitical risks due to unstable political situations in regions, such as Ukraine and Taiwan. There have also been cases in which raw materials could be secured due to natural disasters, or cases in which the use of raw materials was restricted due to the introduction or revision of laws and regulations.

In response to such risks, the Company will take measures such as increasing its procurement sources to multiple sources and increasing its stock of raw materials from normal times to ensure the stable continuation of business.