- Home

- Sustainability

- Chemical Substances Management

Environmental Measures

- Environmental Philosophy and Principles

- Response to the Recommendations of TCFD

- Environmental Management

- Setting Environmental Targets

- Action to Reduce the Environmental Impact

- Chemical Substances Management

- Environmentally Friendly Products

Chemical Substances Management

Minimizing Chemical Substance Risks

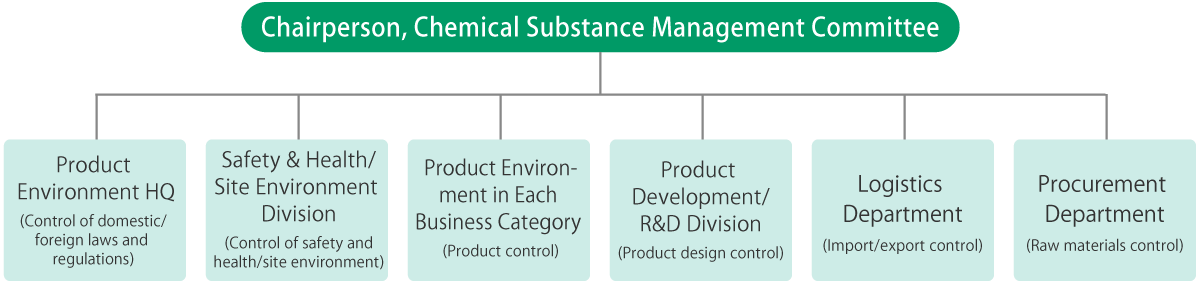

The Dexerials Group believes that thorough compliance in the management of chemical substances is indispensable to continued provision of safe and secure products to our customers in the future. To put this belief into practice, we have established and operate the Chemical Substance Management Committee, consisting of members from all divisions that are involved from the introduction of raw materials to product shipment. To ensure the proper management of chemical substances used in the Company, this committee shares information and considers responses.

In fiscal 2022, this committee met every month to share the latest legal information and discussed responses.

Organization Chart of the Chemical Substance Management Committee

Organization Chart of the Chemical Substance Management Committee

Response to the Pollutant Release and Transfer Register (PRTR) Law

At Dexerials, based on the PRTR system of the Act on Confirmation, etc. of Release Amounts of Specific Chemical Substances in the Environment and Promotion of Improvements to the Management Thereof, we grasp* and report the amount of substances released and transferred.

We use a lot of organic solvent-based solvents to produce adhesives and adhesive tapes, resulting in high emissions of toluene and other substances. These organic solvents are reused as energy by recovering the volatile gases generated during the manufacture of adhesive tapes and burning them in a boiler to exchange heat.

The amount of substances emitted and transferred at each business site in fiscal 2022 is as follows.

- * We have adopted a method of distributing the actual purchase value of chemical substances to the amount of emissions and transfers using a distribution factor (a method in which the amount of chemical substances transferred and released in the manufacturing process is set as a coefficient, and the actual amount corresponding to fluctuations in the actual purchase value is calculated).

Amount of PRTR Substances Released and Transferred in Fiscal 2022

| Plant | Chemical substance | Release/transfer volume calculation (t) |

|---|---|---|

| Kanuma Plant | Acrylic acid and its water soluble salts | 0.081 |

| n-Butyl acrylate | 0.777 | |

| Antimony and its compounds | 0.061 | |

| Ethylbenzene | 0.142 | |

| Xylene | 0.132 | |

| Toluene | 5.360 | |

| Hexamethylene diacrylate | 0.369 | |

| Nickel | 0.003 | |

| Dexerials Photonics Solutions Corporation | Nickel compound | 0.160 |

| Manganese and its compounds | 0.083 |

Responses to Laws and Regulations Relating to Chemical Substances

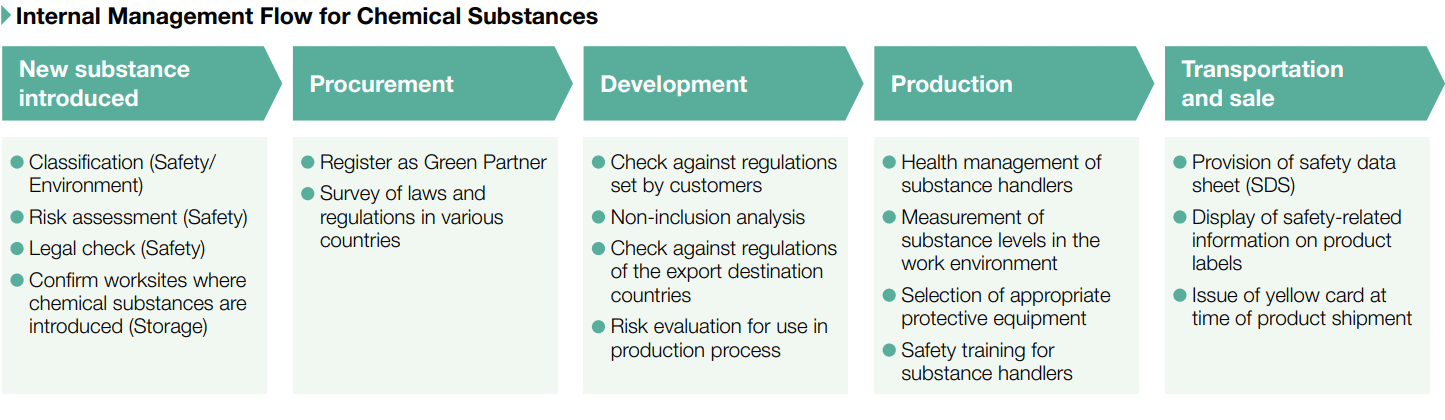

We investigate, check, and comply with regulations ranging from the purchase of raw materials to product design, manufacture, distribution, import and export, etc., to ensure that the Company responds appropriately to chemical substance laws and regulations in Japan and overseas, such as the Act on the Evaluation of Chemical Substances and Regulation of Their Manufacture, etc., and EU REACH Regulation.

Although imports and exports of chemical substances into or out of Japan and overseas may require procedures such as notifications and registrations, we respond appropriately to such regulatory requirements through local sales or manufacturing subsidiaries or consulting companies.

Appropriate Management of Chemical Substances

Because chemical substances have risk of adverse effects on environment and health, we have strengthened our use management by assessing the risk of all chemical substances introduced and classifying them into our own categories using risk assessment method.

The standards of classification are based on laws and regulations and the results of the GHS classification* to correctly determine the degree of risk impact.

We conducted a 100% risk assessment of chemical substances submitted for introduction in fiscal 2022.

- *GHS Classification: GHS, or the “Globally Harmonized System of Classification and Labelling of Chemicals,” is a classification standard adopted by the UN in July 2003 for chemicals according to types of hazards

Education on Chemical Substances Management

Since the Dexerials Group frequently uses chemical substances, we provide employees with education through e-learning, internal training programs, and virtual reality (VR) systems regarding legal requirements, such as the Poisonous and Deleterious Substances Control Law, and handling of chemical substances to allow them to simulated experience accidents involving chemical substances.

In fiscal 2022, we also began educating Kyoto Semiconductor(current Dexerials Photonics Solutions Corporation) employees who recently joined the Group. We provide compliance education to ensure adherence with domestic and foreign laws and regulations in the import and export of products and developed products.

Group education

Training session using VR

Visualization of Chemical Substance Laws and Regulations

We are also engaged in making information on laws and regulations on chemical substances in each relevant country easily viewable, so as to ensure appropriate management of chemical substances on a continuous basis.

In fiscal 2022, we identified early the details of proposed regulations on chemical substances that have a significant impact on our Company. We then shared the schedules for the regulations internally and discussed how to respond to them throughout the Company.

Internal Web Portal to Regulatory Information on Chemical Substances

Internal Web Portal to Regulatory Information on Chemical Substances

Formulation and Dissemination of the Dexerials Group Code of Conduct

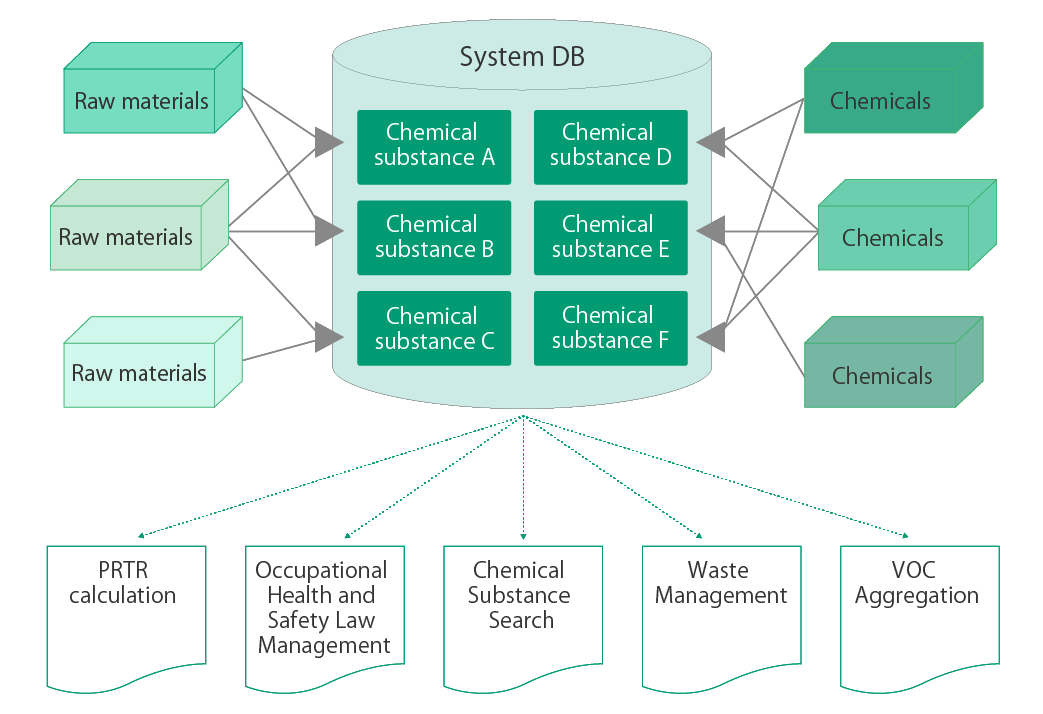

The Dexerials Group uses a system to manage raw materials that are purchased and chemicals/reagents that are widely used by development divisions. Under the system that we operate, chemicals are recorded in a chemical substance database so that the data can then be output by item for PRTR totals and other objectives.

This is useful for preventing compliance violations, as it can be widely used for investigations into the use of chemical substances by individual manufacturing

divisions, R&D divisions, regulations or substance at sites in Japan and overseas, and to respond to revisions in applicable laws.

Comprehensive Management System for Chemical Substances

Comprehensive Management System for Chemical Substances