- Home

- Research & Development

- Overview of Dexerials Technologies

- Material technology

Material technology

Since its establishment, Dexerials Corporation has been developing wide range of functional materials used in latest electronic devices of the times. Variety of adhesive materials for use under numerous conditions, adhesive film showing conductivity only in one direction, resin to protect optical disc surface, inorganic optical devices required for bright projectors, and materials which dramatically improve visibility, to mention a few.

Material compounding technology, know-how and vast amount of design data accumulated over half a century are used to develop challenging materials owning new functions and values.

Compounding technology

This technology is essential for creating appropriate function in required application by combining various raw materials.

Since starting liquid adhesive business in 1963, Dexerials has amassed a vast store of experience and know-how of adhesive materials in response to changes in market trends. Such valuable information is shared among engineers engaged in each development filed, to be used for creating new products with characteristics matching customer requirements.

Here, we will introduce some examples which solved our customers' problems using material and compounding technology.

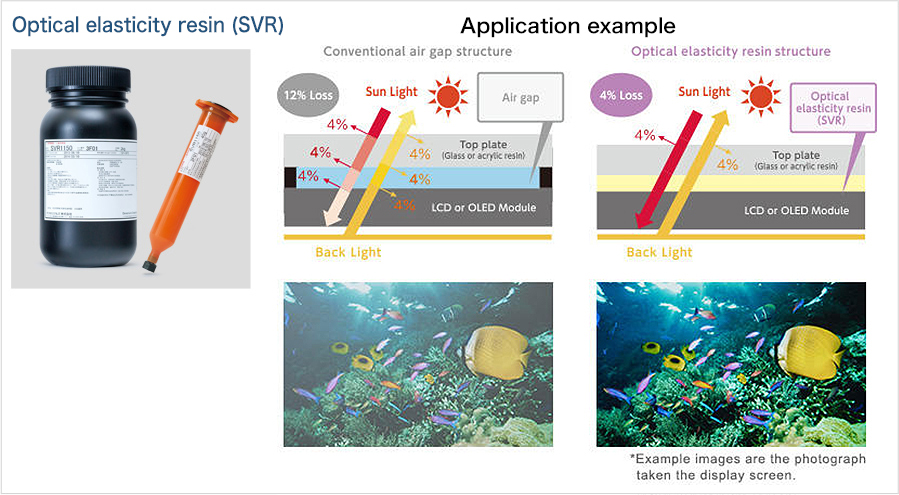

Technology to improve visibility and contrast

Air gap between protective glass and display device (such as a liquid crystal display Panel or (*) OLED panel in notebook PCs or smartphones) will produce reflection at interfaces which lead to degradation of visibility.

In order to suppress undesirable interface reflection, the refractive index of resin need to be equal to that of protective glass as much as possible.

At the same time, materials must be compounded so that the resin has low cure shrinkage rate and low elastic modulus to reduce the risk of deteriorating uniformity of graphics displayed on the panel. Uniformity is disrupted when the panel cell gap dimension changes during curing process of the filled resin.

By understanding multiple characteristics required for display panels and by using our compounding technology developed to the present, we are providing high value-added products such as optical elasticity resin (SVR) mentioned above.

※ OLED : Organic Light Emitting Diode

Examples of products using this technology

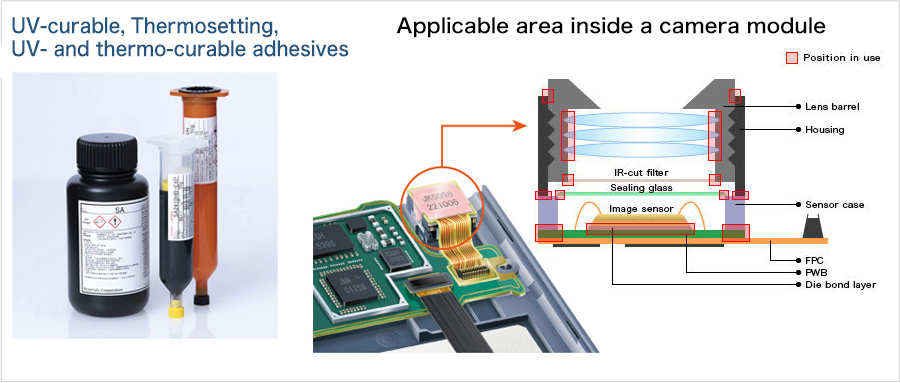

Technology to instantly fix multiple small components with high accuracy

We have seen a great progress in performance of cameras imbedded in smartphones. Optical active alignment and high-precision bonding technology are essential for manufacturing extremely precise and downsized camera modules.

Furthermore, since components and device are becoming smaller, area to apply adhesive material is decreasing year by year. Under such condition, it is necessary to fix components in a short time in order to increase productivity of latest camera modules.

In addition, diverse engineering plastics are used to achieve required performance and cost, which means that in many cases, components with different coefficients of linear expansion and surface conditions need to be bonded. Moreover, optical parts need to be positioned with extreme care due to increased number of pixels in image sensors.

With our proprietary compounding technologies for UV- and thermo-curable resin, we are serving customers requiring adhesives that can cure in a short time while owning viscosity matching to their production process.

We will continue developing unique high-performance adhesives in a speedy manner for our customer’s needs, by utilizing our amassed compound technologies, and contribute to the evolution of camera module performance.

Examples of products using this technology