About Our

Products

- Home

- Products

- Double coated tapes

- Low-Dk/Df bonding sheets

Double coated tapes

Low-Dk/Df bonding sheets

Bonding sheets with a low dielectric constant for high-speed transmission FPCs

-

- Product name

- D5320P

-

- Features

-

- This is an excellent adhesive sheet for materials such as liquid crystal polymer (LCP) and modified polyimide (Modified-PI) with lower dielectric constant, and for low-roughness copper foils for high-speed transmission. It is also excellent in resistance to solder reflow.

- It is excellent in low-Dk/Df characteristics (low dielectric constant and low dielectric loss tangent), and suitable for interlayer adhesion of high-speed transmission FPCs.

- Its small changes in dielectric characteristics relative to changes in humidity contribute to stabilizing signal transmission performance.

- Existing FPC manufacturing equipment can be used since this product is capable of bonding at 180°C.

- Being tack-free at RT, it shows good workability in bonding processes (hot pressing).

- It can be stored at RT, ensuring easy handling.

Safety Data Sheet (SDS) Download

Related articles

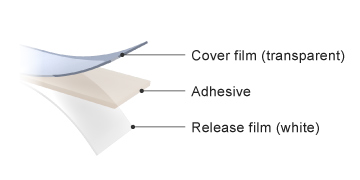

Structure

Specifications

| Product name | D5320P-15 | D5320P-25 | D5320P-50 | |

|---|---|---|---|---|

| Curing system | Epoxy | |||

| Carrier | Non-carrier | |||

| Color (adhesive) | Transparent | |||

| Cover film thickness (µm) | About 38 | |||

| Adhesive thickness (µm) | About 15 | About 25 | About 50 | |

| Release film thickness (µm) | About 38 | |||

| Bonding strength (N/10mm)*1 |

Modified-PI/Cu | 13.0 | 15.0 | 18.0 |

| LCP/Cu | 7.5 | 8.5 | 10.0 | |

| Dielectric constant *2 | 2.36 | |||

| Dielectric loss tangent *2 | 0.0028 | |||

| St'd size (width & length) | 250mm x 100m / 500mm x 100m | |||

| Warranty period from manufacturing | 6 months | |||

- *1 90° peeling strength measurement (after two cycles of 260°C reflow)

*2 At a frequency of 10 GHz - Recommended curing conditions:

■Vacuum quick press + oven-curing

Vacuum quick press conditions: 170 to 190°C, 50 s or longer, 2.0 to 4.0 MPa (holding vacuum for 10 to 30 s)

Oven-curing conditions: 180°C, 60 to 120 min

■Pressing

Press conditions: 160 to 190°C, 60 min or longer, 2.0 to 3.0 MPa (holding vacuum for 10 to 30 s)

・Circuit boards of high-speed transmission devices such as those used for 5G communications

・Wiring substrates between an antenna module and the main substrate installed in a smartphone

1.Bonding strength on various type of substrate (90° peeling strength)

Test Piece Condition

Tape width: 10mm

Backing material: CCL (copper clad laminate)

Bonding condition: Use the recommended conditions (pressing)

Reflow condition: Peak temperature of 260°C (holding a high temperature of at least 255°C for 30 s) x 2 cycles

[Measurement conditions]

Measuring condition: 23°C±5°C 60%±20%RH

Peeling speed: 50 mm/min

Results

(N/10mm)

| 90° peeling strength | Product name | Heat treatment | Modified-PI | LCP |

|---|---|---|---|---|

| D5320P-15 | None | 14.0 | 7.0 | |

| After reflow | 13.0 | 7.5 | ||

| D5320P-25 | None | 16.0 | 8.0 | |

| After reflow | 15.0 | 8.5 | ||

| D5320P-50 | None | 18.0 | 9.5 | |

| After reflow | 18.0 | 10.0 |

2. Dielectric characteristics in moisture absorption

| Dielectric characteristics | Product name | Dielectric constant | Dielectric loss tangent | |

|---|---|---|---|---|

| D5320P | Initial | 2.36 | 0.0028 | |

| After moisture absorption *1 | 2.36 | 0.0028 | ||

- *1 Moisture absorption conditions: 40°C/90%RH 96 hours

caution

Note on the characteristic data given - Data on the characteristics of the products described in this page based on the results of evaluations carried out by the company. This does not guarantee that the characteristics of the product conform with your usage environment. Before use, review the usage conditions based on evaluation data obtained from the equipment and substrates actually used.