About Our

Products

- Home

- Products

- Thermal conductive sheet

- Thermal conductive sheet Standard type

Thermal conductive sheet

Thermal conductive sheet Standard type

Standard type featuring high thermal conductivity and flexibility that rapidly conveys heat to heat sinks.

-

- Product name

- GX30000DS series

-

- Features

-

- Thermal conductivity:3.5 W/m·K, Hardness:40(Shore OO)

- Highly flexible with excellent thermal conductivity that swiftly conducts heat to heat sinks.

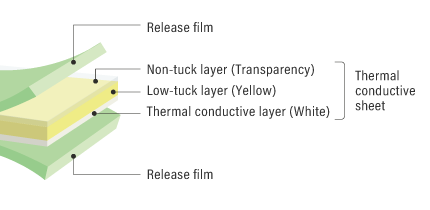

- Excellent workability and reworkability due to its three-layer structure of a low-tuck layer, the main thermal conductive layer and non-tuck layer.

- It has a tack-free layer suitable for contact with uneven surfaces that are prone to oil bleeding.

- Features low molecular-weight siloxane gas volatility, minimizing the risk of contact fault to components such as substrates even over prolonged periods of usage.

- Halogen-free with high levels of flame resistance.

Related articles

Structure

Specifications

| Product name | GX30000DS series | Remarks |

|---|---|---|

| Main component | Silicone | - |

| Color | Yellow/White | - |

| Available thickness (mm) *1 | ≧ 1.5 Increments of 0.5 |

- |

| Hardness *2 | < 40 | Shore OO ASTM D2240 |

| Thermal conductivity (W/m·K) | 3.5 | Estimated bulk thermal conductivity |

| Flame retardance | - | UL94 File No.E63260 |

- *1Thickness of only a thermal conductive sheet. A release film is not included.

- *2Hardness is measured by stacking the sheets to a thickness of 10 mm or more.

Effective in heat conduction for IC chip, LED substrate and power supply.

Relationship between thermal resistance, compression ratio and pressure

Test Piece Condition

Sheet area: 3.14cm2

Measuring condition: 23°C±5°C 60%±20%RH

Thermal conductive sheet temperature: 55°C

Unit of thermal resistance: °C・cm2/W

Results

caution

Note on the characteristic data given - Data on the characteristics of the products described in this page based on the results of evaluations carried out by the company. This does not guarantee that the characteristics of the product conform with your usage environment. Before use, review the usage conditions based on evaluation data obtained from the equipment and substrates actually used.