About Our

Products

- Home

- Products

- Optical elastic resin (SVR)

- Optical elastic resin Hybrid type for small-to-medium sized FPDs

Optical elastic resin (SVR)

Optical elastic resin Hybrid type for small-to-medium sized FPDs

Hybrid type, combining the advantages of liquid resin and pressure sensitive adhesive. Effective in increasing visibility and contrast of screens on devices such as mobile devices and automotive display devices.

-

- Product name

- HSVR330

-

- Features

-

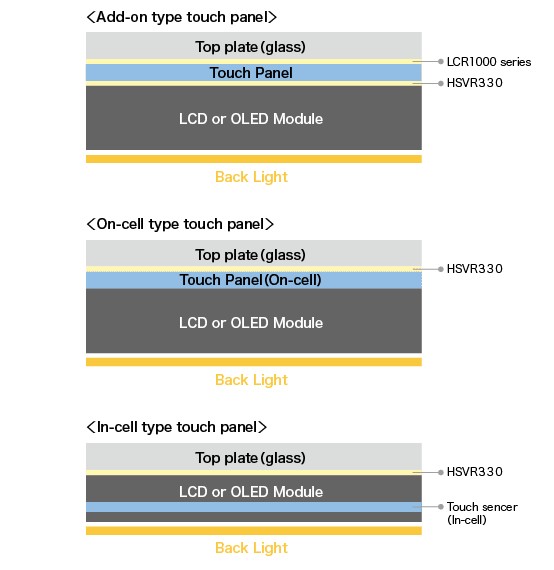

- Coating on the cover glass and filling air gaps with the resin contributes to realizing thinner panels with improved high visibility and high contrast.

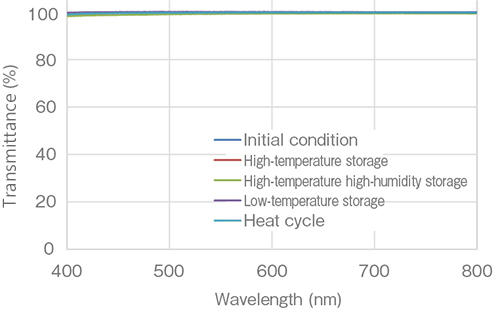

- While maintaining outstanding optical properties of SVR which has high transmittance and resist color deterioration, Hybrid SVR product design enables the realization of high optical reliability.

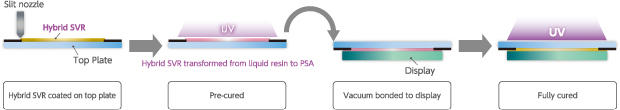

- Film lamination equipment can be utilized for optical lamination since Hybrid SVR is transformed into a PSA during pre-curing process.

- Since UV-curing shrinkage is progressed before lamination, there is little shrinkage at main bonding. It contributes the suppression of color unevenness.

Specifications

| Product name | HSVR330 | |

|---|---|---|

| Pre-curing condition [mJ/cm2]*1 | 500~1,400 | |

| Fully-curing condition [mJ/cm2]*2 | ≧ 1,000 | |

| Viscocity [mPa・s]*3 | 5,300 | |

| Hardness*4 | E12 | |

| Refractive*5 | solid | 1.48 |

| Elastic Modulus [Pa] *6 | 25 ° C | 1.2 x 106 |

| Keeping temperature [°C] | 10~30 | |

- *1 LED 365nm

- *2Metal-halide lamp

- *3Rheo-meter @25°C

- *4Durometer (Code E)

- *5Abbe @25°, D-line(589nm)

- *6DMS method: @1Hz

Lamination processes

Suitable for small-to-medium sized display panels including air gaps, e.g.for smartphone, tablet PC and notebook PC.

【The optical elastic resin structure for touch panel】

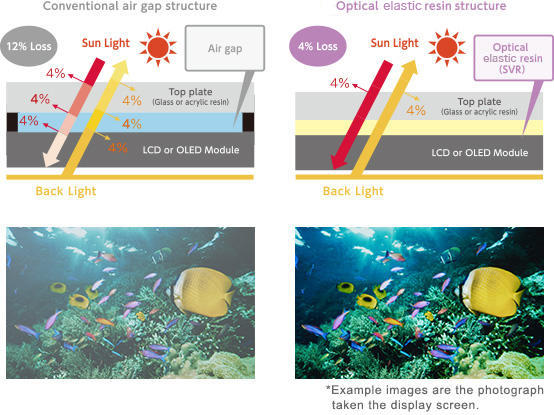

1. Difference between the air gap structure and the optical elastic resin structure

2. Storage test (Optical properties)

Test Piece Condition

Sheet width: 40mm x 70mm x 0.95mm

Coating thickness: 0.15mm

Instrument: Ultraviolet-visible-spectrophotometer UV-2450 (SHIMADZU)

[SVR with a thickness of 0.15 mm coated between two glasses (size: 40 x 70mm; thickness: 0.4 mm)]

| Test condition | Time duration of test | |

|---|---|---|

| High-temperature storage | +95℃ | 1000h |

| High-temperature high-humidity storage | 60℃/95%RH | 1000h |

| Low-temperature storage | -40℃ | 1000h |

| Heat cycle | -40℃⇔85℃ | -40℃:30min 85℃:30min 1000cyc |

Results

Transparency

Hue

| Reliability conditions | L* | a* | b* | Yellowness index |

Haze(%) |

|---|---|---|---|---|---|

| Initial condition | 99.9 | -0.03 | 0.04 | 0.26 | 0.2 |

| High-temperature storage | 99.9 | -0.08 | 0.15 | 0.44 | 0.2 |

| High-temperature high-humidity storage | 99.7 | -0.04 | 0.29 | 0.73 | 0.7 |

| Low-temperature storage | 99.9 | -0.02 | 0.04 | 0.27 | 0.3 |

| Heat cycle | 99.9 | -0.04 | 0.14 | 0.44 | 0.3 |

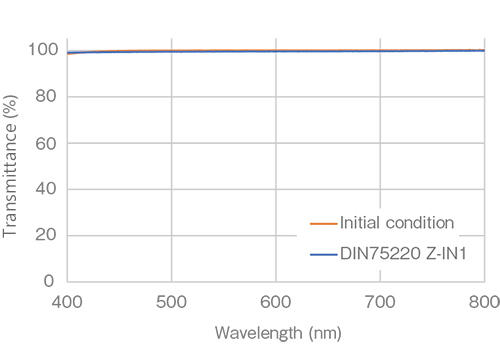

3. Exposure test (Optical properties)

Test Piece Condition

Sheet width: 40mm x 70mm x 1 mm

Coating thickness: 0.2mm

Instrument: Ultraviolet-visible-spectrophotometer UV-2450 (SHIMADZU)

Test condition: DIN75220 Z-IN1

[SVR with a thickness of 0.2 mm coated between two glasses (size: 40 x 70 mm; thickness: 0.4 mm)]

Results

Transparency

Hue

| Reliability conditions | L* | a* | b* | Yellowness index |

Haze(%) |

|---|---|---|---|---|---|

| Initial condition | 99.9 | -0.07 | 0.16 | 0.47 | 0.2 |

| DIN75220 Z-IN1 | 99.8 | -0.02 | 0.15 | 0.47 | 0.3 |

caution

Note on the characteristic data given - Data on the characteristics of the products described in this page based on the results of evaluations carried out by the company. This does not guarantee that the characteristics of the product conform with your usage environment. Before use, review the usage conditions based on evaluation data obtained from the equipment and substrates actually used.