About Our

Products

- Home

- Products

- Double coated tapes

- Special resin base hotmelt double coated tapes

Double coated tapes

Special resin base hotmelt double coated tapes

For applications where strong adhesiveness is required, such as mutual adhesion of metal materials, and adhesion of a metal material and a plastic material.

-

- Product name

- D3600

-

- Features

-

- Fills cavities and clearances for strong bonding in hot melting processes.

- The tape is tack-free at room temperature, enabling die-cutting without release paper.

Safety Data Sheet (SDS) Download

Related articles

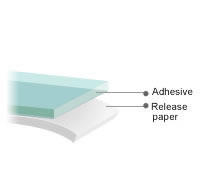

Structure

Specifications

| Product name | D3600 |

|---|---|

| Main component | Polyester |

| Carrier | Non-carrier |

| Color | Translucent |

| Adhesive thickness (µm) | About 50 |

| Release paper thickness (µm) | About 130 |

| Bonding strength (N/20mm x 20mm) *1 |

2,550 |

| St'd size (width & length) | 510mm x 100m |

| Warranty period from manufacturing date | 12 months |

- *1 Shear strength (Bonding temperature 150°C)

Ideal for a mass-production scale adhesion process of brass plates of VTR terminals and glass epoxy base materials and nameplate parts.

1. Bonding strength under different temperatures (Shear strength)

Test Piece Condition

Substrate (1): Stainless steel plate (0.5mmx25mmx100mm)

Substrate (2): PC / ABS plate(4mmx25mmx100mm)

Bonding area: 20mm x 20mm

Bonding condition: Temperature / 100°C to 200°C, Time / 3sec, Pressure / 0.5MPa(5kgf/cm2)2)

Measuring condition: 23°C±5°C 60%±20%RH

Peeling speed: 20mm/min

[Left at RT for one day before measurement]

Results

(N/ 40mm2)

| Shear strength | Product name | Bonding temperature | |||||

|---|---|---|---|---|---|---|---|

| 100 ° C | 110 ° C | 120 ° C | 130 ° C | 140 ° C | 150 ° C | ||

| D3600 | 1,407 | 1,736 | 2,197 | 2,481 | 2,545 | 2,550 | |

| Shear strength | Product name | Bonding temperature | ||||

|---|---|---|---|---|---|---|

| 160 ° C | 170 ° C | 180 ° C | 190 ° C | 200 ° C | ||

| D3600 | 2,609 | 2,614 | 2,677 | 2,839 | 3,242 | |

2. Bonding strength at different temperature (Push out test)

Test Piece Condition

Substrate (1): Stainless steel plate(1.0mm x 50mm x 100mm)

Substrate (2): PC,ABS plate(2mm x 38mm x 64mm)

Bonding area: 20mm x 35mm / 2 pieces

Bonding condition: Temperature / 120°C to 140°C, Time / 3sec, Pressure / 0.5MPa(5kgf/cm2)

Measuring condition: 23°C±5°C 60%±20%RH

Pushing speed: 10mm/min

[Left at RT for one day before measurement]

Results

(N/ 1.4cm2)

| Push out test | Product name | Measuring temperature | ||

|---|---|---|---|---|

| 120 ° C | 130 ° C | 140 ° C | ||

| D3600 | 39.2 | 73.6 | 250.2 | |

3. Impact force resistance (Drop test)

Test Piece Condition

Substrate (1): Stainless steel plate (1.0mm x 50mm x 100mm)

Substrate (2): PC, ABS plate (2mm x 50mm x 100mm)

Bonding area: 10mm x 10mm

Bonding condition: Temperature / 120°C to 140°C, Time / 3sec, Pressure / 0.5MPa(5kgf/cm2)

Measuring condition: 23°C±5°C 60%±20%RH

Height: 1.5m

Weight: 300g

[Left at RT for one day before measurement]

Results

| Impact force resistance Drop test |

Product name | Measuring temperature | ||

|---|---|---|---|---|

| 120 ° C | 130 ° C | 140 ° C | ||

| D3600 | 17.0 8.0 |

26.0 20.0 |

30 or less 30 or less |

|

- *The test piece is dropped to concrete. Record the numbers when the test piece peel off.

caution

Note on the characteristic data given - Data on the characteristics of the products described in this page based on the results of evaluations carried out by the company. This does not guarantee that the characteristics of the product conform with your usage environment. Before use, review the usage conditions based on evaluation data obtained from the equipment and substrates actually used.