- Home

- Sustainability

- Occupational Health and Safety, Disaster Prevention

Relationships with Society

- Quality Management

- Procurement

- Human Resource, Diversity, Workplace

- Initiatives for Respecting Human Rights

- Health and productivity management

- Occupational Health and Safety, Disaster Prevention

- Contribution to Local Communities

Occupational Health and Safety, Disaster Prevention

The Dexerials Group implements employee training, along with reinforcement and improvement work to facilities, in an effort to prevent or minimize damage from disasters and accidents which potentially could have a serious impact on business. We are also making various efforts to ensure that our employees work in a healthy and hygienic manner.

Safety Philosophy, Basic Policies

Safety Philosophy

Under the corporate vision of “Value Matters —Unprecedented innovation, unprecedented value”, the Dexerials Group understands that safety is essential to creating new value and improving quality and is committed to continuously providing safe and healthy business sites and manufacturing workplaces.

Basic Policies

The Dexerials Group, promote occupational health and safety management systems,improves the climate of safety in work sites in all areas of business operations and makes various efforts to prevent serious accidents, aiming to reduce accidents and risks and ensure stable business continuity.

- 1.We understand and comply with domestic and overseas laws, ordinances and regulations related to health and safety.

- 2.We carry out risk assessment appropriately and work on the following as important actions.

- (1)Operational/Equipment safety: We identify risks in on-site operations and equipment and ensure that mitigation measures are implemented.

- (2)Work environment safety: We consistently adhere to measures regarding the risk of hazardous materials and flow management in order to maintain and improve the work environment.

- (3)Health management:We implement prevention and improvement activities, such as measures for health problems caused by remote work and overwork, mental health (implementation of stress checks), and measures for prevalent health problems.

- (4)Traffic safety: We work on traffic safety education and raising awareness to reduce the number of traffic accidents.

- (5)Disaster prevention measures: We established BCM*2 which connects initial responses and the BCP*1 to protect human life, operations and our stakeholders.

- 3.We improve the awareness and knowledge of safety and disaster prevention through practical operations, education and training to develop human resources.

- 4.In regard to safety and disaster prevention, we actively cooperate with the government and local communities while driving participation and communication forward.

- 5.By auditing and reviewing the effectiveness of our occupational health and safety management system, we make every effort to stimulate our health and safety activities.

- *1 BCP: Business Continuity Plan

- *2 BCM: Business Continuity Management

Education and training

Through the introduction of new and the updating of our existing education and training systems, we will create environments that will facilitate each and every employee’s learning in an efficient and effective manner. Including specialized education for health and safety officer appointees and managers, this is leading to the understanding and enhancement of risk management and safe work behavior.

Health and safety officer appointees and manager education

For the education of foremen, we added training opportunities via webinars, thereby making it possible to accommodate a large number of participants and business situations. The provision of flexible learning environments is leading to assured learning. In addition, for special training for laser and forklift operators, in-house qualified instructors customize the curriculum to suit the workplace conditions, making it possible to provide training suitable for actual operation. After learning those skills, the trainees can work smoothly in the field.

Main education and training program content

We have a permanent “Safety Workshop” where employees can learn about occupational safety in a comprehensive manner, and safety education is provided to each and every employee. At the “Safety Workshop”, we can experience simulated industrial accidents that have occurred in the past using special equipment. We are also enhancing the quality and environment of education on health and safety and disaster prevention by introducing a “virtual reality (VR) hazard experience system” that allows employees to virtually experience serious industrial accidents.

VR training for traffic safety

As a new digital tool to prevent traffic accidents, we conduct education that utilizes virtual reality (VR).

By experiencing in virtual form, a variety of content, such as the causes of traffic accidents and road layouts, participants are improving their sensitivity to hazards, understanding the importance of safe driving, and changing their behavior to be more careful when actually driving. At Dexerials, commuters by private car account for the majority, at 76%.

We are aiming to prevent traffic accidents by placing VR tools at each location and creating environments that enable flexible experiences.

Hazard simulation equipment

By utilizing actual equipment that reproduces past workplace accidents, we are conducting education that enables employees to experience in a realistic manner the impact on human lives and operations as well as the hazards that can lead to physical injuries to workers.

Focusing on human factors, which are one of the causes of workplace accidents, as well as impatience, arrogance, and overconfidence due to work experience, participants can learn about the importance of prioritizing human life and adhering to rules. By having participants actually experience, for example, the ignition and explosion when static electricity is charged or discharged or being caught by a rotating cylinder, we are aiming to improve their ability to predict hazards by reproducing in visual form the amount of charge and intuitively feeling the impact of a piece of equipment.

VR training for hazardous situations

In addition to the existing hazard simulation equipment, we are conducting education using VR to experience hazards. Although we have maintained a record of zero workplace accidents caused by equipment, there are still accidents caused by supplementary tasks. At Dexerials, we conduct VR education that makes use of content tailored to the sources of hazards in the workplace, based on the causes of past workplace accidents and risk assessments.

Through this VR training, participants experience the fear of disasters through “Scared Straight,” an educational method that dares them to experience fear in order to change their behavior, and learn safety awareness, understanding of the importance of procedures, and how to follow work procedures, leading to safe work and behavior.

Safety workshop hands-on training

Hazard simulation equipment

VR training for hazardous situations

VR training for traffic safety

Prevention and Continuous Improvement

Digitalization of occupational safety and health management system

The “Risk assessment system”, which was established and digitized in fiscal 2021, was further updated in fiscal 2022 to enable functional linkage and cross-functional data sharing. Continuous initiatives like these are leading to faster operations and more active safety activities. In fiscal 2023, we will continue to digitize our internal audit system based on our occupational safety management system while aiming to raise the levels of our health and safety activities.

Risk assessment patroles

Risks that could cause similar accidents or the recurrence of an accident are selected from known workplace accident factors by utilizing a risk assessment system. Based on that system, we are able to prevent the occurrence of the workplace accidents—caused by excessive-strain movements and coming into contact with high temperatures—that occurred last year by conducting patrols by experts who shared the information across organizations or connected that information to countermeasures.

Equipment safety checks

To continue to ensure worker safety and remain in compliance when installing equipment for production or development uses, equipment safety checks are conducted from three health and safety management perspectives: work environment management, work management, and health management. Since we started the operational use of the equipment installation system, there have been no workplace accidents or incidents involving operational impacts caused by equipment. We are also moving forward with the horizontal deployment of the system to our affiliated companies.

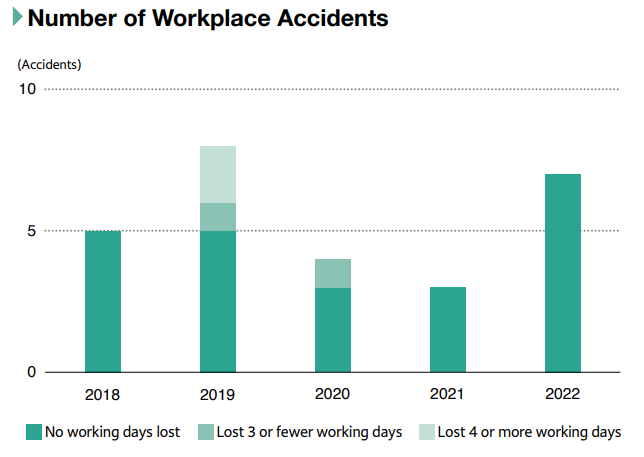

Occurrence of Workplace Accidents

Based on its safety philosophy and basic policies, Dexerials is working to prevent serious accidents by setting annual targets.

With regard to workplace accidents throughout the Group in fiscal 2022, there were no work-related fatal accidents, workplace accidents, and occupational illnesses involving lost working days.

However, as we found that, after having analyzed the results for fiscal 2022, there had been a year-on-year increase in the number of accidents that had not involved lost working days among employees with less than one year of work experience, we analyzed the causes of the workplace accidents and promoted initiatives designed to link them to the autonomous and continuous management of risk reduction measures.

Dexerials Group Activity Results in Fiscal 2022, Japan

| Category | Policies | Targets | Results |

|---|---|---|---|

|

Identify on-site work/equipment risks, implement mitigation measures | Zero workplace accidents involving lost working days | Zero workplace accidents involving lost working days (Seven accidents that did not lost working days result in loss of working days) |

|

Implement risk countermeasures and flow management for hazardous substances, improve and maintain working environments | ||

|

Prevention/improvement of health disorders caused by remote work/ excessive working hours, mental health, and measures for people requiring observation |

|

Observation, promotion of smoking cessation |

|

Reduce occurrence of traffic accidents through traffic safety education and awareness-raising initiatives | Zero traffic accidents | Traffic accidents: 15 |

|

Put in place business continuity management (BCM) that connects initial response with BCP to protect human lives, businesses, and stakeholders | Zero operational impacts | Zero operational impacts |

- Note: Excluding part of Dexerials Photonics Solutions Corporation