- Home

- Research & Development

- Technical Notes

- Particle-arrayed Anisotropic Conductive Film (ACF) ArrayFix®

Technical Notes

Particle-arrayed Anisotropic Conductive Film (ACF) ArrayFix®

ACF, used in many electrical devices such as smartphones today , was developed in 1970 when heat-seal and zebra connectors were widely used. 7 years later, we became the world’s first company to start shipping ACF to customers.

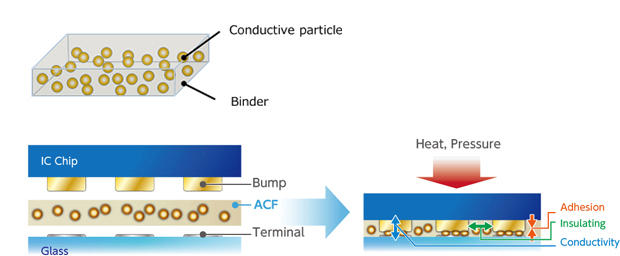

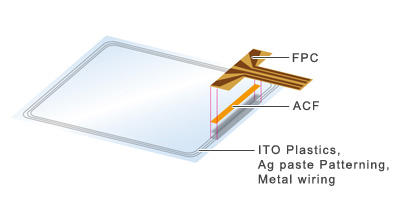

Mechanism of ACF bonding

ACF is a film-type conductive adhesive with uniformly dispersed conductive particles in heat curing resin, enabling conduction vertically and insulation between terminals simultaneously.

When Heat and Pressure is applied to connect between glass substrate and IC chip, particles trapped on bump surface act as conducting material. Meanwhile, insulation coated particles which did not get trapped are reallocated between terminals and are fixed by heat curing binder to prevent short circuit.

Type of ACF

We are offering many types of ACF, such as FOB/FOG/COG, to keep in line with growing application.

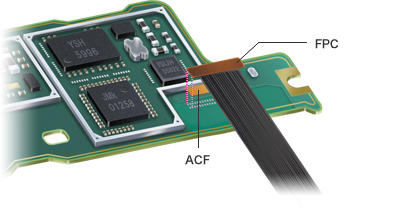

FOB(Film on Board)

Used to mount FPC(flexible printed circuitry) on a circuit board.

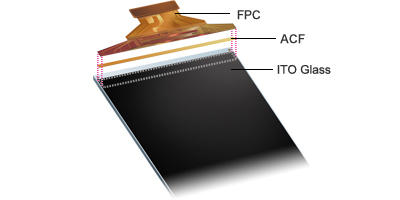

FOG (Film on Glass)

Used to mount FPC on glass substrates of Display, PC, smartphones, etc.

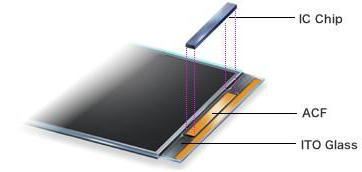

COG (Chip on Glass)

Used to mount IC chip directly on glass substrate especially in thin devices such as smartphone and tablet.

Due to the narrow bonding area and close distance between terminals, superb conduction reliability is required,

FOP(Film on Plastics)

Used to mount FPC on touch panel’s plastic substrate .

Compared to glass, plastic is weak against heat.

Therefore, FOP is designed to adhere under relatively low temperature in a short time.

There are also COB(Chip on Board), COF(Chip on Film),FOF(Film on FILM), etc.

Suitable for fine pitch connection - Particle-arrayed Anisotropic Conductive Film (ACF), ArrayFIX®

As IT mobile devices get more sophisticated and higher resolution displays appear, mounted components such as ICs need to be downsized, and naturally, pitch between terminals become closer and closer. Under this fine pitch trend, demand for trapping conducting particles in a limited small area is required.

To meet this demand, we introduced smaller sized particles while increasing the number of particles. By increasing the number of particles, particles trapped on bumps will increase, however, particles left between terminals will also increase which can be a risk for short circuit. We need to minimize such risk.

Foreseeing that fine pitch trend will continue, in 2014, we developed a new technology named ArrayFix, which can trap enough particles in a small limited area without increasing the risk of short circuit.

Particle alignment technology

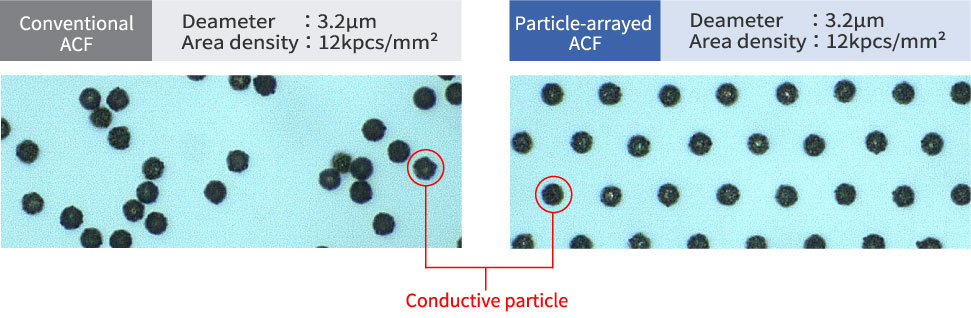

We designed a new ACF where particles are aligned in a specific interval, which is excellent for obtaining just the number of particles necessary for conduction (not too few and not too much).

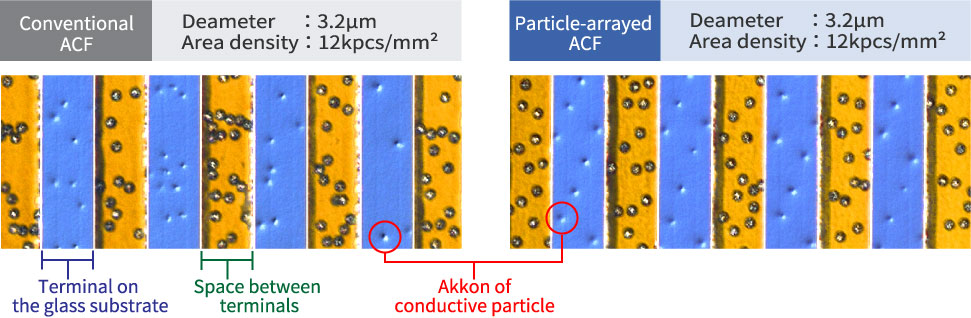

We also developed a special resin for this new ACF that make it difficult for particles to move during bonding process (when pressure and heat are applied). Since particles left between terminals cannot move so easily, the risk of short circuit is minimized

Anisotropic Conductive Film(ACF):How conductive particles are dispersed

Appearance of areas bonded with ACF

- Diameter:Φ3.2μm Area density:12,000pcs/mm2

- FPC terminal size:Terminal width35μm (Line/Space = 17.5μm/17.5μm)

- Bonding conditions :Temperature of 170°C, time of 5 sec., pressure of 4.5 MPa

- Glass substrate :Thickness of 0.5mm

* ArrayFIX is a resisterd trademark of Dexerials.