- Home

- News Release

- 2020

- Productized

Effective for emergency repair for oil leaks in electric equipment such as transformers Productized "INFRA-AID ™" UV Curable Sealant "UVS-1000C"

New Product

2020.05.26

Dexerials Corporation (Headquarters: Shinagawa-ku, Tokyo, Representative Director and President: Yoshihisa Shinya, herein after called our company) productized “INFRA-AID TM” UV Curable Sealant “UVS-1000C,” which is effective for emergency repair for oil leaks in electric equipment such as transformers.

The products have already been sold on a trial basis to domestic power companies, steel companies and petrochemical companies which have transformers, and introduced to TEPCO Power Grid, Incorporated (Head Office: Chiyoda-ku, Tokyo, President: Yoshinori Kaneko) as an emergency repairing material for oil leaks.

Power companies, steel companies and petrochemical companies use a lot of transformers. These transformers need maintenance due to long-term use. Oil is used for insulation and cooling in transformers, but oil leakage may occur due to the deteriorated gaskets of flanges and valves, which are connecting parts of pipes, and overall corrosion in equipment and pipes that pass oil. When oil leaks occur, it can cause not only oil loss, but also the functional failure of equipment and environmental pollution in and out of plants, so prompt action is required.

■ Image of oil leaks

■ Image of oil leaksTo fundamentally solve the oil leaks that tend to occur in transformers, it is necessary to drain the oil after stopping the operation temporarily and conduct an extensive overhaul such as changing the deteriorated parts. As this overhaul requires a lot of time and cost, emergency repair to seal leaky areas with sealant is conducted as a temporary cure. However, there was the problem that the oil leakage could not feasibly be stopped during repair because the sealing material did not adhere to the areas that were coated with oil, and it took time to cure, leading to oil leakage in the repaired area.

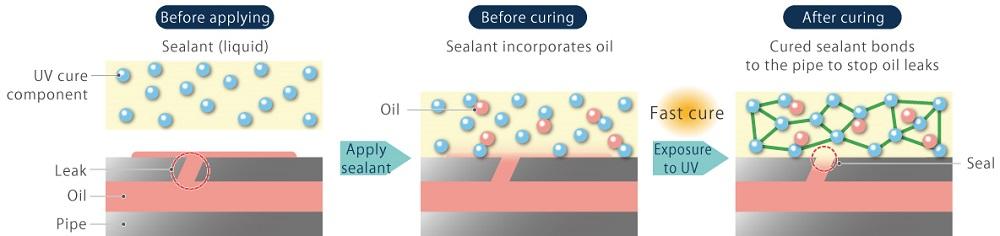

UV Curable Sealant “UVS-1000C,” which has been productized by our company, is a special sealant for repairing oil leaks, which can adhere to oily surfaces and cure in a short time.

As the sealant, which is compatible with and incorporates oil, is applied to the adhesive surface of pipes, bonding is possible even in areas that are coated with oil. In addition, instant curing by applying UV can seal the area before leak paths start to develop. There is no waiting time for complete curing, which saves man hours. In addition, it is one component type, which does not require mixing before use, so it is easy to handle and customers can work by themselves.

Our company is aiming to resolve social issues with high technology and establish sustainable growth through business expansion in a new domain. The development of the product is a part of these activities, and in order to resolve social issues like oil leaks and provide customers with new value, they were developed by using knowledge and know-how of the composition of various adhesive materials that our company has cultivated in the electronics domain.

Our company will propose the product for use in the repair of small and medium-sized mechanical equipment and automobile parts, as well as for electric equipment such as transformers to expand sales. In addition, we will develop repairing material for infrastructure maintenance where gas leaks and water leaks are repaired by utilizing our own elemental technology, and aim at business growth by improving product structure of INFRA-AID.

■Product information

| Model | UVS-1000C | |

|---|---|---|

| Type | 1 component UV curable acrylic | |

| Property(Uncured/Cured) | White viscous liquid/White solid | |

|

Adhesion to various materials *1 |

Good | Stainless steel, Cast-iron, Rigid PVC, Acrylic (PMMA), Glass, Galvanized steel, Carbon steel, Brass, Aluminum |

| Fair | Olefin resin (PP, PE) | |

| Very poor | Silicone resin, Fluorine resin | |

| Adhesion to oily surfaces Shear strength[MPa] *2 | w/o Oil film *3 | 8 |

| with Oil film *4 | 6 | |

| Breakdown voltage [KV/mm] *5 | 52 | |

| Shelf life | 2 years from the date of manufacture (stored unopened at room temperature) |

|

| Net weight | 200g | |

| Container | Cover:PP Container:PE | |

- *1with#1000 sanding

- *2SUS304 with#1000 sanding Shear Tester@ 0.2 mm/s, 25℃

- *3After degreasing

- *4Dried after immersed in 15 wt% transformer oil A hexane solution

- *5Conforming to ASTM D149

- Curing conditions:1J/cm2 @365nm

■How to use

| ① | ② | ③ | ④ |

|---|---|---|---|

|

|

|

|

| Prepare surface by removing paint, rust or grease | Apply sealant with a brush | Apply UV for curing | Complete |

- * “INFRA-AID” is our company’s trademark.

This product, INFRA-AID UVS-1000C, has been renewed with a more user-friendly container and is being sold by AirMore Co., Ltd. as “LeakAID LL-100-LA180G” since June 2024 onwards.

For inquiries about this product, please contact AirMore Co., Ltd.