About Our

Products

Case study of Introduction of Micro LED Displays | Anisotropic Conductive Film (ACF)

- Higher Reliability of LED Chips on the Micro LED Displays

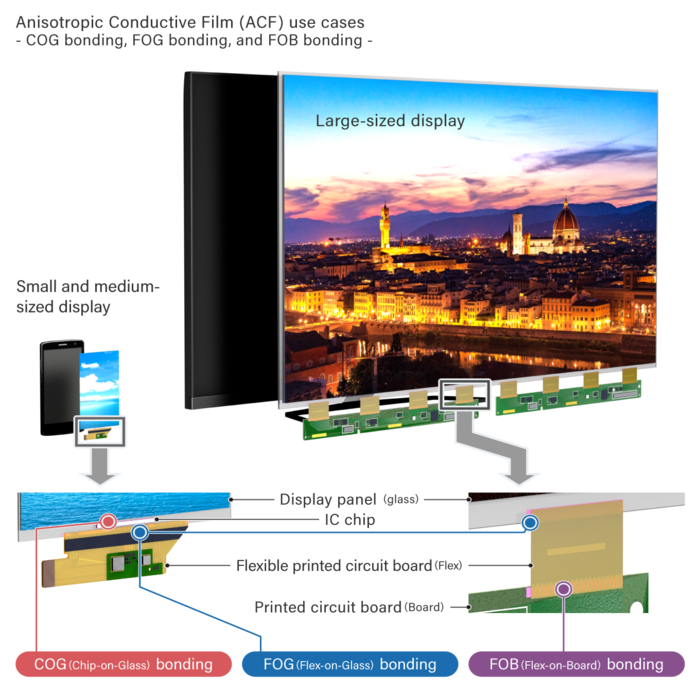

- ArrayFIX is a particle-arrayed anisotropic conductive film (ACF) from Dexerials. This ACF ensures the formation of ultra-high-density electronic circuits using a proprietary technology to arrange conductive particles precisely in the film. ArrayFIX improves the reliability of the electrical connectivity of LED chips particularly on micro LED displays that have especially fine pitches.

View information about this product

Application

Realization of high-definition, high-intensity, high-contrast displays

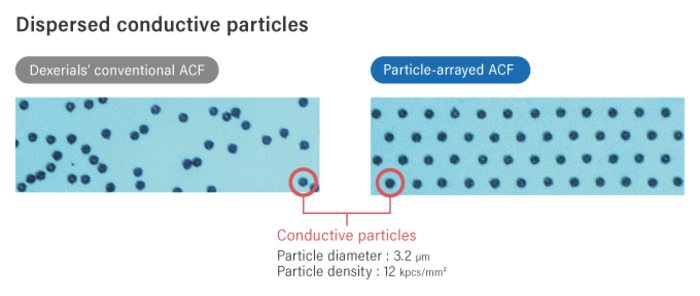

Reducing the size of the conductive particles in the ACF made it possible to support the smaller terminal bonding areas of miniaturized LED chips. A product with denser particle alignment has also been added to the lineup to support high-resolution micro LED displays.

Removal of display defects and higher panel yield

As conductive particles in the ACF are fixed after connection, insulation is maintained even between minute electrodes, avoiding short-circuiting at the time of connection. In addition, ArrayFIX supports a technology to transfer the ACF only to the mounting section using a laser to mount LED chips onto the substrate. This enables the replacement (repair) of defective LED chips, which is an issue when manufacturing micro LED displays, thereby improving the yield of display panels and enhancing productivity.

Higher productivity by reducing mounting costs and simplification of the panel manufacturing process

As low-temperature mounting is possible and pretreatment for mounting is not required, the manufacturing process is simplified, reducing costs. ArrayFIX can also be used to reduce connection defects during manufacturing and improve productivity.

Product characteristics

Particle alignment technology for stable electrical connection

As conductive particles are regularly aligned, terminals can reliably catch particles and ensure stable conduction even for the same particle density. In addition, particle positions are precisely controlled for even placement, effectively preventing short-circuiting even in fine-pitch connections.

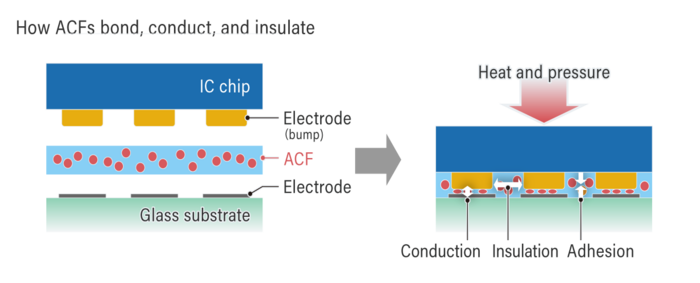

Adhesion using a thermosetting resin

ACF has a structure in which conductive particles are dispersed in a thermosetting resin that functions as the adhesion layer. This adhesion layer fixes particles and serves as the insulating layer.

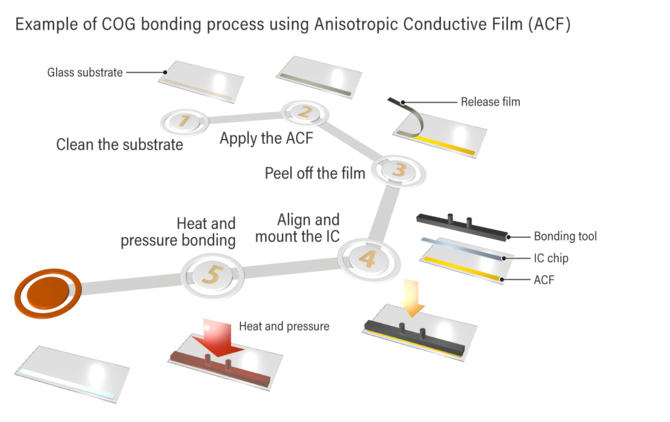

Procedure for mounting parts using the anisotropic conductive film (ACF)

The anisotropic conductive film (ACF) is a film-type adhesive. Parts are mounted by adhering the ACF to the substrate, placing parts on the ACF, and bonding them through thermal compression. A wide lineup of films with thicknesses of 10 to 45 μm and widths of 0.5 to 20 mm is available.

[Mounting procedure ]

Step 1. Wash the surface of the substrate to be connected.

Step 2. Adhere the ACF to the substrate and apply heat and pressure without removing the release film.

Step 3. Peel off the release film from the ACF.

Step 4. Accurately align the electrodes of the IC chip you want to connect.

Step 5. Connect the IC chip by applying heat and pressure again.

Product information

Optical Semiconductor