- Home

- News Release

- 2018

- Achievement of Development to realize Pb-free Fuse Elements for Surface mounted Type Fuse Self Control Protect

Achievement of Development to realize Pb-free Fuse Elements for Surface mounted Type Fuse Self Control Protector, and The Patent acquisition.

New Product

2018.09.25

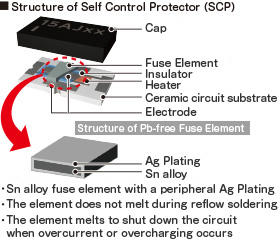

Dexerials Corporation (Takashi Ichinose, Representative Director and President, Shinagawa, Tokyo) is pleased to announce that it has developed and acquired a patent for technology to realize Pb-free*1 fuse elements for surface mounted type fuse, Self Control Protector (SCP), used as secondary protection devices for Li-ion battery packs. In addition, we have also reviewed the ceramic circuit substrate material structure, which includes Pb*2 that is exempted from the scope of the RoHS Directive to realize a completely Pb-free SCP.

Dexerials’ SCP is a fuse used for secondary protection that melts the fuse element to shut down the circuit when overcurrent and overcharging occur due to malfunction of the primary protection that controls charging and discharging Li-ion battery packs fails to function as it should. Since their appearance on the market in 1994, SCPs have become widely used in PCs and many other applications that use Li-ion batteries such as Smartphones, electric power tools, cordless cleaners and electric motorcycles.

To withstand reflow soldering - an excellent component-mounting method, internal fuse elements of SCP must have a melting point that will ensure that they will not melt even if heated to temperatures of 230 - 260℃. On the other hand, to ensure that the elements will melt quickly when lithium-ion battery packs overcurrent or overcharging occurs, the melting point also needs to be as low as possible, but at least 260℃. To satisfy these two requirements, conventional products use high melting-point solder*2 containing lead to which usage restrictions imposed by the RoHS Directive do not apply as their main constituent. Up to the present time, realize Pb-free elements was difficult owing to there has been no alloy available that combines both a melting point close to that of high melting-point solder and fluidity. However, over a period of more than twenty years to the present, Dexerials has made advances in product performance and downsizing and amassed a wide range of material technologies. Now, after considering the impact of Pb on the environment and the possibility that regulations will become more stringent in the future, we have succeeded in developing and acquiring a patent for a fuse element that does not use Pb.

The Pb-free fuse element that Dexerials has developed forms by applying Ag plating with a melting point of 962℃ to the surface of Sn rich alloy with a melting point of 217℃. During reflow soldering, the element retains its shape and, conversely, when protective operation is triggered by phenomena such as overcurrent or overcharging, the element heat up to temperature higher than reflow soldering it, become in liquefaction of the inner Sn alloy. Moreover, when the dissolution*3, a phenomenon that melts solids into liquid, occurs, and the entire fuse element can cut with melt by significantly lower temperature than melting point of Ag owing to Ag melt into the liquefied Sn alloy, thus it achieves realization of equivalent functions to conventional fuses without using Pb.

In addition, Dexerials has realized a completely Pb-free SCP owing to review of the material structure of circuit substrate. Dexerials’ SCP has already been adopted by major Smartphone manufacturers.

*1 The European RoHS Directive that restricts usage of hazardous substances defines Pb-free as a Pb content of 1,000 ppm or less.

*2 Materials such as high melting-point solder with a Pb content of 85% or more by weight, and glass, ceramic and Pb compound materials used in electrical and electronic components fall outside the scope of the RoHS Directive.

*3 Dissolution: Phenomenon in which other substances dissolve into a liquid to form a homogenous phase (JIS K 0211: 2013)