- Home

- [Under development] Noise suppression thermal conductive sheet Carbon fiber type

[Under development] Noise suppression thermal conductive sheet Carbon fiber type

Thermal conductive sheet, just a single sheet of which is capable of both noise suppression and high thermal conductivity in vertical direction for heat dissipation

-

- Product name

- EX10000K3 series

-

- Features

- Capability of high suppression of GHz-band high frequency noise is attained through the mixing with magnetic powder. Moreover, the high thermal conductivity of 20 W/m·K in a vertical direction makes it suitable for heat dissipation and noise suppression for LSIs handling high-speed, large-capacity data processing, such as those required for 5G communication.

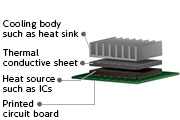

Structure

Specifications

| EX10000K3 series | Note | ||

|---|---|---|---|

| Features | High thermal conductivity; Noise suppression | - | |

| Thermal conductivity(W/m·K) | 20 | Estimated bulk thermal conductivity | |

| Main component | Silicone base | - | |

| Color | Gray | - | |

| Hardness | 40~60 | Shore OO ASTM D2240 |

|

| Available thickness(mm) | 0.5~4.0 | - | |

| Specific gravity | 4.1 | - | |

| Volume resistance(Ω・cm) | 10 | JIS K7194 | |

| Relative permeabilityµr″ | 1GHz | 1.8 | S-parameter method |

| 2GHz | 2.1 | ||

- *

Thickness of a thermal conductive sheet only. Release films are not included. Available in 0.1 mm increments

The values in the table above are not guaranteed product values.

Suppression of high-frequency noise and heat dissipation of large amounts of heat generated in LSIs and other devices used for applications such as mobile devices, TVs, PCs, wireless communication base stations, wired communication base stations, servers, and automotive equipment

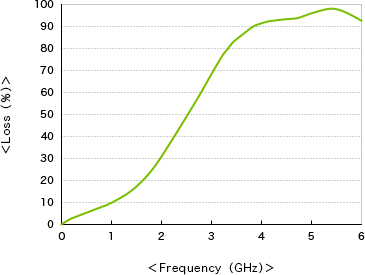

1.Conductive noise suppressing effect

Test Condition

-

- Sheet width

- 20mm×20mm

-

- Sheet thickness

- 1.0mm

-

- Substrate

- Micro-strip line(MSL) circuit board

-

- Measuring condition

- 23°C±5°C 60%±20%RH

-

- Tester

- Network analyzer

[2cm square sheer is placed on the MSL and the ioss is evaluated by S11 and S21]

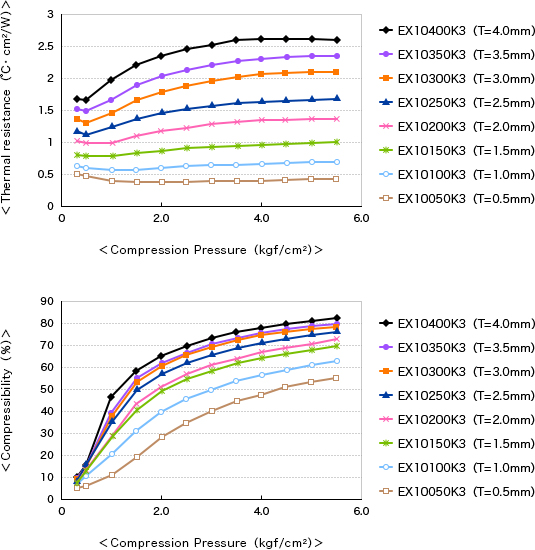

2.Compression Pressure and Thermal Resistance; Compression Pressure and Compressibility

Testing conditions

-

- Specimen area

- 3.14cm2

-

- Measuring condition

- 23°C±5°C 60%±20%RH

-

- Setting electric power of heater

- 24W

-

- Unit of thermal resistance

- °C・cm2/W

caution

Note on the characteristic data given - Data on the characteristics of the products described in this page based on the results of evaluations carried out by the company. This does not guarantee that the characteristics of the product conform with your usage environment. Before use, review the usage conditions based on evaluation data obtained from the equipment and substrates actually used.