- Home

- [Under development] Low-κ thermosetting tape for FPCs

[Under development] Low-κ thermosetting tape for FPCs

Thermosetting tape for high-speed transmission FPCs with excellent low dielectric constant and bonding strength; capable of bonding at 180℃.

-

- Product name

- D5200 series

-

- Suitable use

- Interlayer adhesion of high-speed transmission FPCs

-

- Features

-

- Low transmission loss due to low dielectric constant

- Existing FPC manufacturing equipment can be used because the tape thermally cures at 180℃.

- This Novel formulation optimizes low dielectric constant with a high bonding strength. This technology enables the manufacture of highly reliable FPCs.

Structure

Specifications

| Product name | D5200 series | Note | |

|---|---|---|---|

| Release film thickness (μm) | 38 | ||

| Adhesive thickness (μm) | 25 | Customize 12-50 (μm) | |

| Release paper thickness (μm) | 130 | ||

| Bonding strength (N/10mm) | 13 | 90° peeling strength to copper foil | |

| Standard size (width & length) | 250㎜×100m 500㎜×100m |

||

| Dielectric properties | Dielectric constant (κ) | 2.30 | ASTMD2520 (JISC2565),10GHz |

| Dielectric dissipation factor (DF) | 0.0025 | ||

Suitable for interlayer adhesion of high-speed transmission FPCs used in parts that link antenna and substrate for 5G communication or parts that connect sensors for autonomous vehicles.

1.Dielectric properties

| D5200 series | Liquid crystal polymer (LCP) | ||

|---|---|---|---|

| Initial values | dielectric constant(κ) | 2.30 | 3.0 - 3.4 |

| Dielectric dissipation factor(DF) | 0.0025 | 0.002 - 0.0023 | |

| After aging at 40C /90%/72-hour | Dielectric constant(κ) | 2.30 | 3.0 - 3.4 |

| Dielectric dissipation factor(DF) | 0.0026 | 0.002 - 0.0023 | |

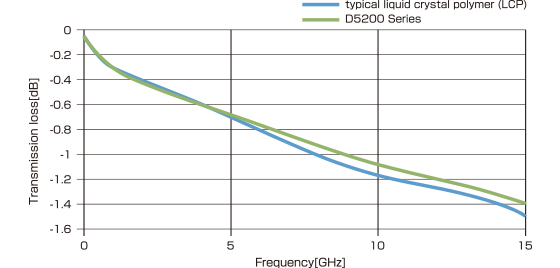

2.Transmission loss

Testing conditions

-

- Microstrip line length

- 100mm

-

- Impedance

- 50Ω

Simulation data

- * Simulation by Dexerials, using properties of a typical liquid crystal polymer (LCP)

caution

Note on the characteristic data given - Data on the characteristics of the products described in this page based on the results of evaluations carried out by the company. This does not guarantee that the characteristics of the product conform with your usage environment. Before use, review the usage conditions based on evaluation data obtained from the equipment and substrates actually used.