- Home

- News Release

- 2016

- Commercialization of ArrayFIX, Particle-arrayed Anisotropic Conductive Film (ACF) Featuring Adhesion with Mini

Commercialization of ArrayFIX, Particle-arrayed Anisotropic Conductive Film (ACF) Featuring Adhesion with Minimum Wiring Space of 10μm

New Product

2016.12.07

Dexerials Corporation (Takashi Ichinose, Representative Director and President, Shinagawa City, Tokyo) has commercialized Particle-arrayed Anisotropic Conductive Film (ACF), ArrayFIX PAF300B and PAF300C. These films are more suitable than a conventional ACF for connection with fine circuits.

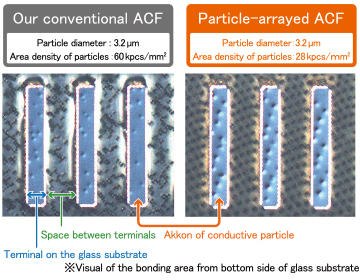

Displays and cameras on smartphones, tablet computers, and other consumer IT devices are currently becoming more sophisticated while mounted components are downsized. With this, there is a higher demand for a greater number of fine wires (fine-pitch connection). We have developed Particle-arrayed ACFs in order to meet the demand for fine-pitch connection. The conductive particles are arrayed and the density of particles is decreased to less than half of that of a conventional ACF. The developed ACFs use a binder that makes it difficult for the particles to move even during bonding. The use of the binder balances opposing characteristics, the insulation property between adjacent terminals and the performance of capturing particles between upper and lower terminals, thereby achieving a stable wiring connection.

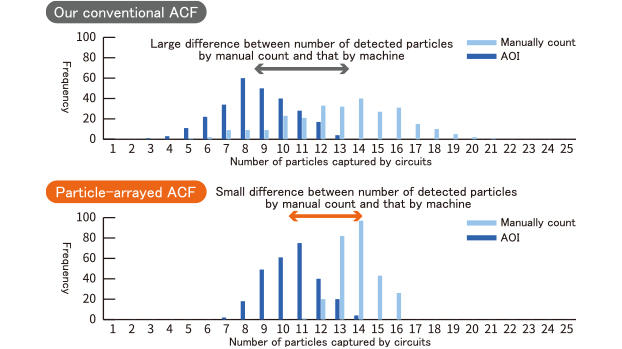

With Particle-arrayed ACFs, the detection accuracy of bonding inspection (akkon inspection) performed by image processing has been enhanced compared to that of a conventional ACF. With the conventional ACF, the conductive particles are dispersed towards the direction of thickness with some variation. Because of this, the particles in conventional ACF are potentially overlapped one another during connecting, and the strength of akkon becomes not uniform. These make it difficult to detect impressions of ACF particles by the akkon inspection. Therefore, there have been cases where a good boning one was misjudged as a defective one. On the other hand, conductive particles of the Particle-arrayed ACFs are arranged in a plane to reduce the variation of the particle positions in the thickness direction. This feature resolves issues on a conventional ACF during the akkon inspection and contributes to improved production yield.

In the past, adoption of Particle-arrayed ACFs has been considered by our customers, and we have provided, connected, and evaluated samples. Several customers have decided to adopt the ACFs for COG connection, including LCD modules and OLED modules. In addition, we are studying and prototyping Particle-arrayed ACFs for Film On Glass (FOG) connection, connection of glass substrates with flexible printed boards. Taking a cue from this commercialization, we aggressively propose Particle-arrayed ACFs.

* ArrayFIX is a trademark of Dexerials.

IC:0.8 mm × 29.8 mm, height of 0.15 mm

IC bump:Gold plating of 12 μm × 80 μm, height of 12 μm

Glass substrate:Thickness of 0.6 mm

Bonding conditions:Temperature of 150°C, time of 5 sec., pressure of 60 MPa

Automatic optical inspection machine (AOI):FPX101AI (Made by Panasonic)

Measurement conditions:×10 imaging by differential interference

Resolution:1μm

* To prevent defective panels from being overlooked,

the AOI is configured so that irregular or low-contrast akkons are not detected.

Product Specifications

| PAF300B | PAF300C | Our conventional product | |

|---|---|---|---|

| Conductive particle diameter(μmφ) | 3.5 | 3.2 | 3.2 |

| Area density of conductive particles(kpcs/mm2) | 20 | 28 | 60 |

| Minimum connection area(μm2) | 400 ※1 | 300 ※1 | 1300 ※2 |

| Minimum space※3(μm) | 10 | 10 | 12 |

- ※1Minimum connection area calculated by our original simulation

- ※2Minimum connection area satisfying an equation of average number of captured particles - 4.5σ ≥ 3

- ※3Space between adjacent terminals