- Home

- News Release

- 2014

- Development of a Particle-Arrayed Anisotropic Conductive Film (ACF) for Chip on Glass (COG) connection with Mi

Development of a Particle-Arrayed Anisotropic Conductive Film (ACF) for Chip on Glass (COG) connection with Minimum Bump space of 10µm

New Product

2014.10.29

Dexerials has newly developed “Particle-arrayed Anisotropic Conductive Film (ACF)” for Chip On Glass (COG) connection which connect the glass substrate of flat panel display with driver ICs. Using Particle-arrayed ACF, the risk of a short circuit occurrence with ICs having lower bump height is reduced, and a fine-pitched connection with minimum bump space of 10µm is achieved. Particle-arrayed ACF contributes to COG connection for next-generation smartphones and tablet PC.

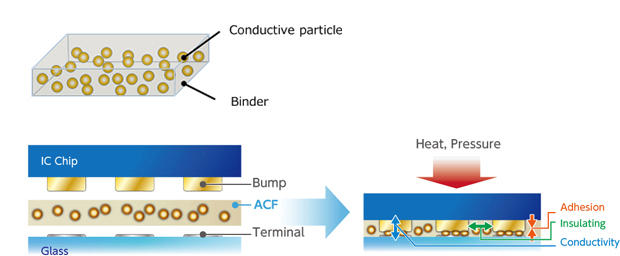

Anisotropic Conductive Film (ACF) is a bonding material that uniformly distributes conductive particles with an insulating coat inside a thermosetting resin binder. When connecting a glass substrate and IC chip, ACF is capable of establishing a connection of multiple substrate circuit electrodes simultaneously by heating and pressurizing. Particles are captured and electrically conducted on the conductor bump surface and particles that are not captured by bumps move between the terminals, but they do not conduct due to the insulating coating on particles, and the thermosetting binder provides a highly reliable adhesion. ACF is widely used in the connection of IC chips in the flat panel displays such as high definition TVs and mobile devices.

■Mechanism and structure of Anisotropic Conductive Film (ACF)

Currently, as high-definition mobile devices, such as smartphones and tablet PC, have increased, there is an even greater demand for fine-pitch connection. By making the particle diameter smaller and increasing the density of particles, we have been achieved ACF connection with small contact area. However, with COG connection, the electrode space of display panel becomes narrower and if the particle density increases too much, the risk of a short circuit occurrence increases. Therefore, increasing the density of particle has been not a perfect solution for small area connection.

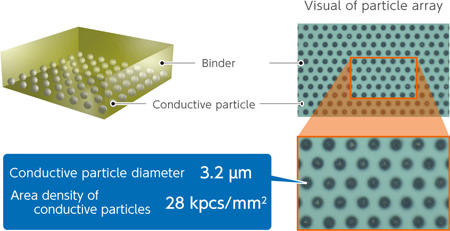

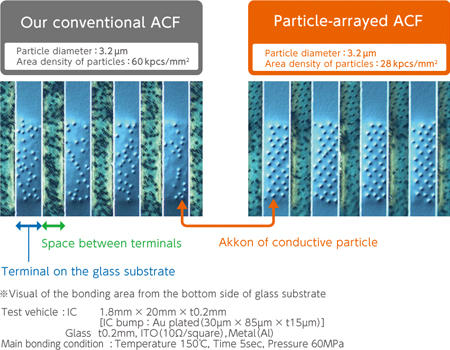

Therefore, to lower the risk of short circuit occurrence and to achieve stable particle capturing, the density of conductive particles are reduced rather than increasing particles, and conductive particles are arrayed at the targeted position. Moreover, unlike a conventional ACF using highly fluid resin as binder for the purpose of making it easy for particles that are not captured by the bumps to escape between the electrodes during bonding process, Particle-arrayed ACF uses a new developed resin with suppressed fluidity to keep the arrayed particles in the original position. By using new resin, we developed “Particle-arrayed ACF” whereby most of the particles do not move during bonding process and the risk of a short circuit occurrence is low.

■Structure of Particle-arrayed ACF

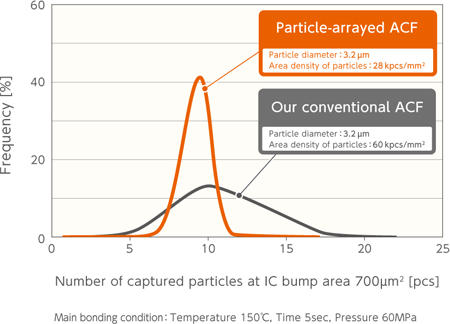

With a conventional ACF, there is variability in the number of particles captured by bump terminals, but in a Particle-arrayed ACF, by controlling the number of particles as shown in *1, the number of captured particles stabilizes, enabling a highly reliable connection and assured conductivity.

■Particle capture performance (*1)

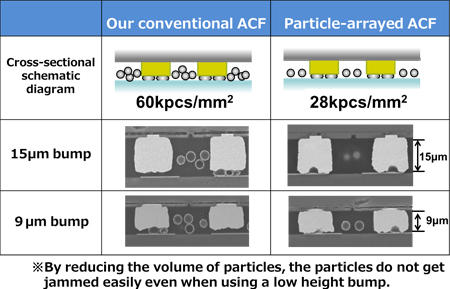

Further, with a small volume of particles, we have confirmed that jamming of particles, that causes short circuiting, does not easily occur even when using a low height bump as shown in *2.

■Cross-sectional comparison of bonding areas (*2)

■Visual comparison during ACF

As explained above, Particle-arrayed ACF born from a new idea is a next generation COG connecting material that enables fine-pitched connection with a minimum bump space of 10µm, and expected to contribute to the improvement of high connection reliability and assured fine-pitched connection of high-definition FPDs, such as smartphones and tablet PC, and IC chips. Furthermore, this material can be used as is with existing bonding machines and hence investment in new equipment is unnecessary.

The patent for this developed product has been applied.

Dexerials will be displaying this product at Display Innovation 2014 to be held at Pacifico Yokohama from Wednesday, October 29 to Friday, October 31. Please come and see us at our booth (booth No. 1401) at the convention.